© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

OW8

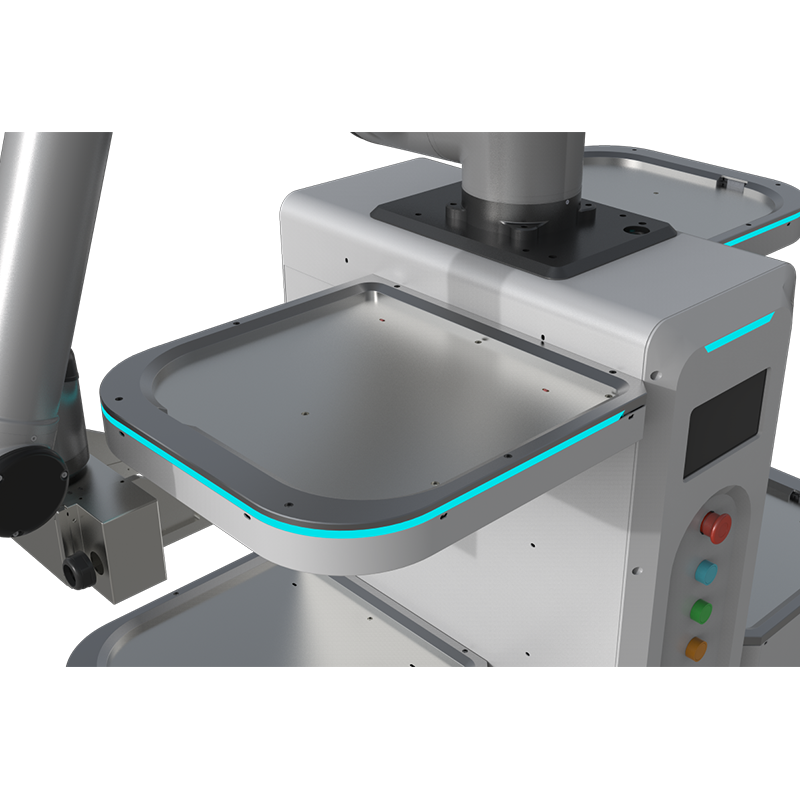

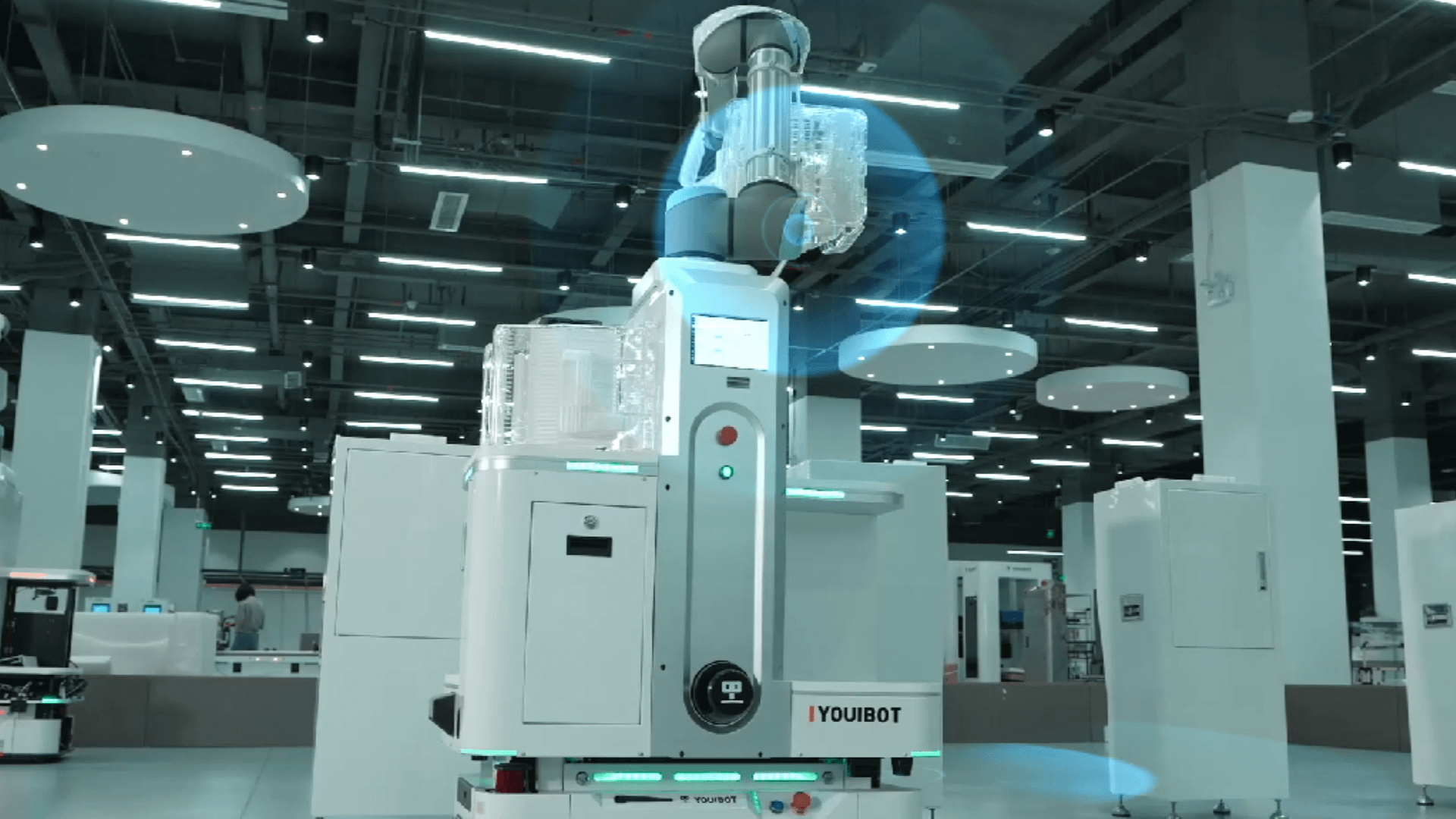

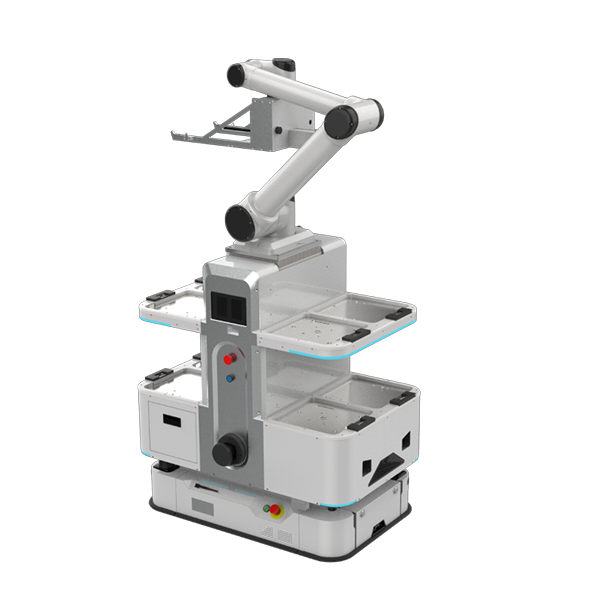

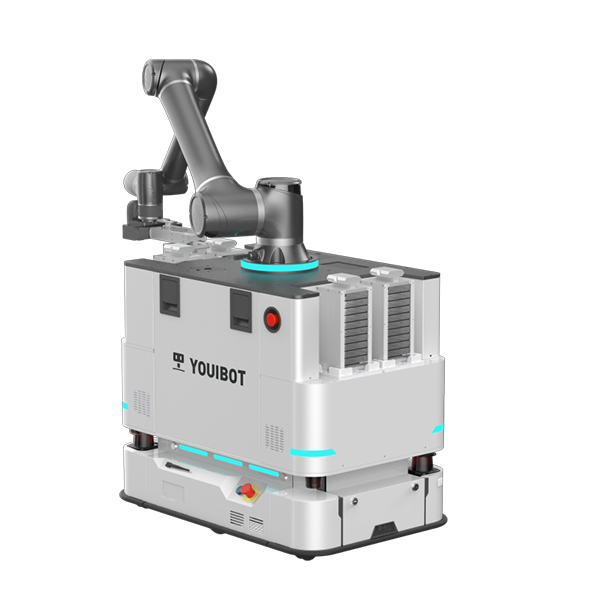

Youibot OW8 is a composite robot equipped with cobot. It offers an automation solution specialized for loading and transferring the 8'' SMIF Pod.

In addition to essential robot safety horizontal detection, OW8 is equipped with a safety and navigation lidar, as well as a side lidar that provides vertical detection.

This advanced technology supports the semiconductor industry's push for greater automation in manufacturing, allowing for more efficient and effective processes.

With the wafer-handling robot OW8, manufacturing operations can be simplified and semiconductor manufacturing automation can be greatly enhanced, thereby increasing productivity and reducing costs.