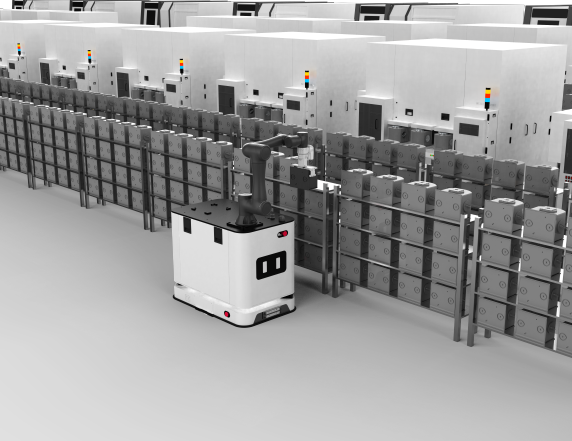

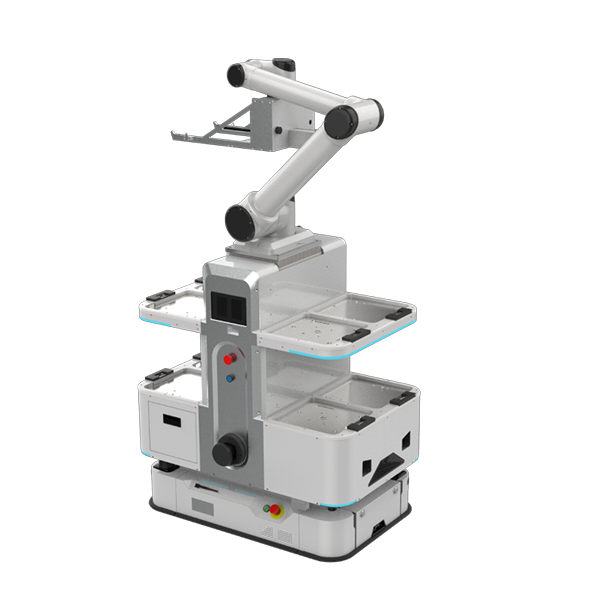

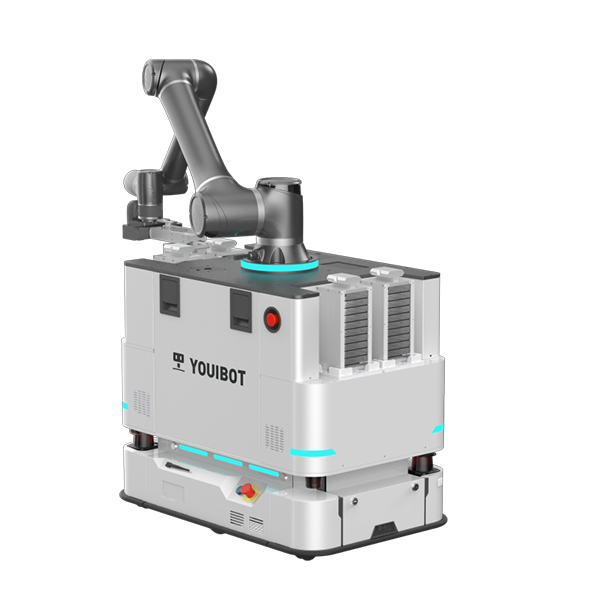

The industrial mobile manipulation robot OW12 from Youibot is specifically tailored for semiconductor automation scenarios. It comes with a cobot that's designed to handle and load/unload 12" FOUP PODs in semiconductor front-end chip manufacturing scenarios.

The cobot has an end gripper and vision sensor that can accurately grasp the 12" FOUP POD at the upper clamping fixture, reducing direct contact with wafers and minimizing vibration impact during lifting.

The robot is designed to minimize vibration impact on the handling object FOUP POD, meeting the conventional standard of vibration ≤ 0.5G for flat ground operation.

With the specially designed electronic shelf, it can handle material from the robot storage position to the shelf storage position while monitoring and uploading the robot and shelf storage position information.