© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

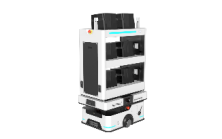

Youibot's industrial mobile manipulationrobots enhance logistics efficiency between 3C industry workshops like stamping, injection molding, and CNC. Our robotic solutions leverage advanced Lifting Series robots, including lift robots Youibot L300 and L1000. These flexible robot platforms automate the precise and timely transport of diverse materials, mitigating delays and errors associated with manual handling. Supported by YOUITMS and YOUIFLEET software, Youibot's robot base solutions ensure seamless integration with third-party systems and efficient robot fleet management, breaking down data silos.

Robot manufacturer Youibot's 3C industry solutions also support customization. With custom-integrated roller conveyors, these robots enable fully autonomous loading, unloading, and material handling. The introduction of collaborative robots in the manufacturing industry has become an emerging trend. With new automation technology, our solution alleviates labor shortages, boosting overall efficiency and agility in the fast-paced 3C manufacturing landscape.

Youibot's robots offer intelligent navigation, precise handling, and flexible automation to optimize workflows and enhance productivity.

Robots provide full-cycle data connectivity, ensuring 100% traceability of logistics information.

With automatic recharging and 24/7 operation, robots deliver continuous, high-efficiency performance.

By redeploying staff to higher-value tasks, robots boost productivity and cut material handling costs.

Robots dynamically adjust to changing conditions, eliminating costly bottlenecks and ensuring smooth operations.

Through continuous quality monitoring and improvement procedures, we ensure high product quality at every stage, from design and manufacturing to testing.

We provide comprehensive one-stop customization services and can customize different solutions according to customers' specific needs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.