© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

Under the trend of increasing the domestic production rate of chips, the expansion of production and efficiency has become a common demand in the industry.

Youibot's industrial logistics solutions for chip production, applied to the whole industry chain links such as wafer manufacturing and chip packaging and testing have helped many manufacturers to complete automation upgrades and achieved the goal of improving efficiency and benefits.

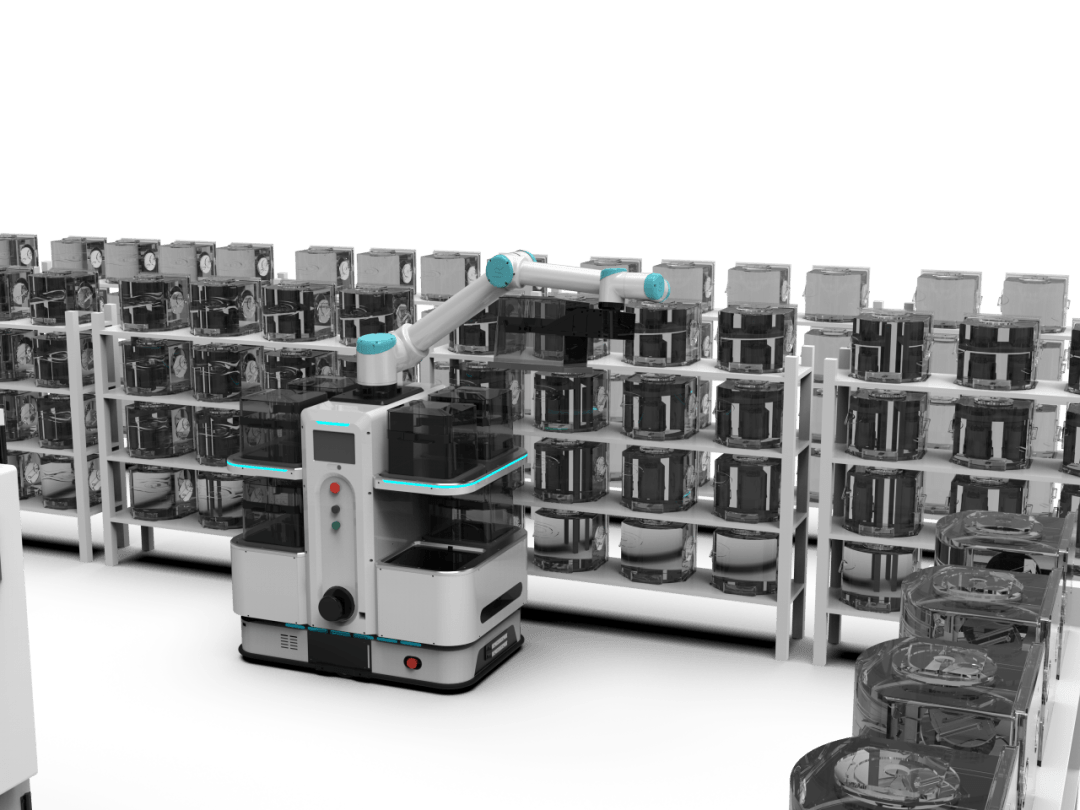

Youibot chip manufacturing logistics

automation solution

Taking circular production as an example, Youibot applies high precision laser SLAM navigation compound shift manipulator robot, equipped with YOUI Pilot navigation system, YOUI Fleet robot scheduling the system, and the YOUI TMS on-site logistics management system, realizing the automatic transfer of wafer cassettes between different processes such as machines, electronic material racks, and storage bins, and at the same time open up the material flow and information flow of the whole production cycle to ensure the entire process of material data. Traceability is to achieve stable, continuous, and efficient wafer production.

Wafer Production Pain Points

PAIN POINTS

Manual handling has large vibration and is easy to pollute, resulting in a low yield rate.

In order to ensure continuous and stable production, a large amount of inventory is accumulated at the line side, occupying the production space.

The technological process is complex, the production process is discrete, the data is not shared between equipment, there are information islands, and the material shortage problem occurs when the machine is not loaded and unloaded in time.

Solution

SOLUTION

1. Perfectly docked with automation equipment such as retractable triggers, conveyor lines, etc., which can match efficient and flexible automatic handling operations in various scenarios of semiconductor production.

Advantages and Values

ADVANTAGE

The pick-and-place height of the wafer handling robot covers 0.2-2.5 meters, the highest in the industry, and the widest range of loading and unloading heights for wafer cassettes, improving the space utilization of the FAB.

Yield improvement

The vibration value of the wafer handling robot is less than 0.1G, and it can meet the requirements of CLASS 1 clean workshop at the highest. It operates stably and improves the yield rate.

Steady beat

# The world's leading semiconductor 8-inch fab smart logistics project

The project is deployed in the world's leading semiconductor 8-inch fab. This factory is a new factory and is currently in the process of ramping up its production capacity. In order to solve the huge and complex task of loading and unloading SMIF Pods every day, more than 10 YOUIBOT wafer cassettes have been introduced. Robots realize flexible and intelligent production.

Through the intelligent scheduling logistics control system of the wafer robot box, the flexible transportation and unmanned automatic loading and unloading of materials between electronic racks, machines, and storage bins are realized. YOUI TMS logistics management system is directly connected to the equipment control system to realize workshop production visualization and production process operation control.

30% Ineffective walking reduction

60% Increased utilization of electronic racks

2% Whole plant efficiency improvement

Digital intelligent management, real-time feedback of production data

Reduce manual work and realize automatic loading and unloading

Learn about YOUIBOT business

By continuing to use the site you agree to our privacy policy Terms and Conditions.