© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

With the rapid development of technologies such as "new-generation information technology", "big data", "cloud computing" and "artificial intelligence", based on the cloud, using industrial internet and 5G technology to build buildings, the flow management, and control platform realizes the automation of the manufacturing process, the visualization of the production process, the data-driven intelligence, and the customization of customer needs, which has become the high-quality development direction of the manufacturing industry.

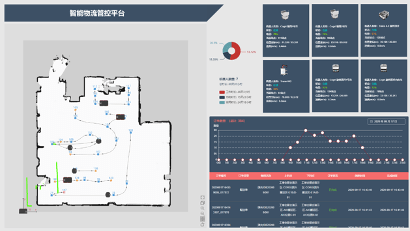

In view of the problems of poor data correlation and poor coordination of the most intelligent logistics systems in the market at present, Youibot has created an intelligent logistics management and control platform. YOUI TMS provides enterprises with a full range of intelligent logistics services and operation control. Through the comprehensive application of industry 4.0, lean management, Internet of Things, big data, Internet +, and other technologies, the goals of system integration, refined management, full-process visualization, intelligent management and control, and business mobilization have been achieved.

Background and Challenges

A variety of factors promote intelligent manufacturing.

The logistics link is in urgent need of an intelligent manufacturing upgrade.

With the in-depth integration of new-generation information technologies such as industrial Internet, big data, cloud computing, and artificial intelligence with advanced manufacturing technologies, the advancement of intelligent manufacturing will be more in-depth, and the technological application of intelligent manufacturing will be further expanded. At present, the wave of intelligence is surging, and the integration of digital technologies such as big data, cloud computing, artificial intelligence, and 5G with traditional industries is accelerating. From intelligent transformation to building an industrial Internet platform, to building digital workshops, unmanned factories, smart factories, etc., intelligent manufacturing has become a breakthrough in the transformation and upgrading of the traditional manufacturing industry. Accelerating the promotion of intelligent manufacturing is an inevitable path for the upgrading the manufacturing industry, and it is also an effective way to form more growth points. Previously, the national policy emphasized that intelligent manufacturing should be the main direction of attack, speeding up the innovation and development of the industrial Internet, and accelerating the fundamental changes in manufacturing production methods and enterprise forms. Intelligent manufacturing is increasingly becoming a major trend and core content of the future manufacturing industry.

Driven by the increasingly diverse consumer demand in the market, product updates and iterations have become more and more common and frequent, forcing companies to shorten and speed up product development and production cycles, further increasing the demand for flexibility in the manufacturing industry. In previous decades, a product could take years to be replaced, however, today a product may only remain on the shelf for months or weeks before being refreshed. As a result, to produce new products, the production line needs to be adjusted more frequently than before, and in these cases, there is an urgent need to increase the flexibility and flexibility of production. In addition, with the disappearance of the domestic demographic dividend, labor costs have risen, and labor has accelerated from the secondary industry to the tertiary industry. The younger generation is reluctant to enter the factory, and there is a "labor shortage" in manufacturing enterprises, forcing manufacturing enterprises to transform and upgrade and improve the level of automation.

In Industry 4.0, intelligent logistics is an important part of promoting development, and the demand for intelligent logistics solutions in industrial manufacturing lies in the coordination of the overall production rhythm, the stability of the scheduling system, and the feasibility of data collection, serving production, and supporting The raw materials, semi-finished products, finished products, and parts are stored and transported inside the factory, focusing on the connection between logistics and production, and running through the entire production process. Materials continue to change their physical form and location over time, either for processing, assembly, storage, handling, and waiting. It can be seen that the poor logistics of manufacturing enterprises will lead to production stoppage and low operational efficiency. The optimization of workshop logistics mainly focuses on rapid response to products, optimization of minimum production scheduling, reduction of inventory, optimization of the logistics process, and guarantee of product quality.

solution

Empowering Industry 4.0, Youibot Intelligent Logistics Management and Control Platform

The intelligent logistics management and control platform of Youi Robot, for the logistics data fragmentation problem in the whole process of material flow from warehousing to the workshop, workshop to the production line, carry out effective collection, analysis, and processing, logistics data empowers production management and operation and creates materials from warehousing to workshop, workshop to production line It also can integrate third-party systems such as MES and WMS, and work collaboratively to provide enterprises with a full range of intelligent logistics services and operation control. Intelligent logistics management and control platform, through the comprehensive application of industry 4.0, lean management, Internet of Things, big data, Internet+, and other technologies, has realized system integration, refined management, full visualization, intelligent management and control, and business mobility.

YOUI TMS System Architecture

Technical advantages

Realize the characteristics of flexibility, intelligence, high efficiency, and wide scenes

The competitiveness of the YOUI TMS program is as follows, which can be achieved Flexible, intelligent, high-efficiency, wide scene Features.

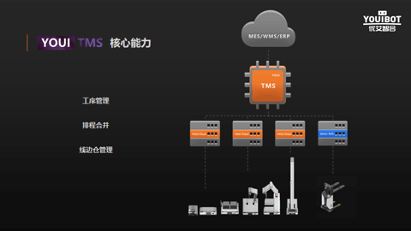

TMS Core Competencies

Flexible configuration: The system business has the characteristics of modularization, which can configure different functional modules according to the on-site logistics and transportation process, and can support users with different permissions to configure different operation modules;

Intelligent scheduling: order timeliness management, dynamic optimal merge allocation, intelligent workshop logistics data visualization analysis, intelligent decision-making and scheduling control;

Lean logistics: Predictive process optimization, realize zero inventory of materials, high-precision all-round control, improve product yield and production efficiency, and achieve lean logistics management;

Cloud service: SaaS service can be provided, supporting private cloud, public cloud, and hybrid cloud deployment;

Cloud management and control: It can create an integrated center of "transportation, management, and end" to realize remote management and control of production line logistics and transportation;

Covering a wide range of scenarios: YOUI TMS is to create a full-process logistics and transportation chain from warehousing to workshop, workshop to the production line, which can cover more application scenarios;

Personalized customization: can provide standard interfaces, support WMS, MES, and other third-party system integration, support customized development, and meet the needs of factory intelligence.

Case implementation effect

Covering multi-scenario applications

At present, YOUI TMS intelligent logistics management and control platform has a large number of application cases in electronic semiconductor, 3C, aircraft manufacturing, automobile, and other industries. YOUI TMS can provide corresponding solutions for different business scenarios, which can be mainly summarized into the following two scenarios: 1) The production line lacks monitoring and the degree of automation is low; 2) The production flow in the production environment is insufficiently connected, resulting in slow production efficiency.

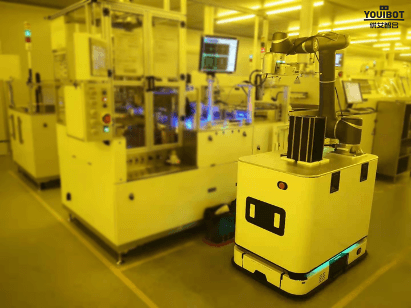

1) Electronic semiconductor application cases

For manufacturing scenarios with incomplete production lines, low degree of automation, and imperfect informatization, it is possible to Through the YOUI TMS intelligent logistics management and control platform, use Modbus, serial communication, TCP, and other communication protocols to connect production line equipment, monitor equipment status and production line production status in real-time, trigger production line tasks by themselves, and distribute tasks to help production line automation.

The semiconductor production workshop has a high cleanliness level, complex layout, small space, and a wide variety of equipment. The equipment in the large-scale production workshop is distributed in clusters, the production process is discrete, the process flow is complex, and the order requirements are flexible, so it is impossible to form a simple and effective assembly line production. According to the business scenario, the logistics management, and control platform is used to easily realize automatic handling operations and enterprise information access. Through the technical support of AI technology, big data, cloud computing, etc., the collection, analysis, and centralized management of on-site logistics data and production data in the workshop can be realized to achieve coverage. The unmanned intelligent production workshop with the whole process of production and logistics has successfully helped the overall informationization of the factory to upgrade, improve the level of production operation management and improve the overall production efficiency.

02) Application cases of the automobile manufacturing industry

Application Outlook

Under the background of Industry 4.0, assisting the industrial transformation and upgrading of manufacturing enterprises

By continuing to use the site you agree to our privacy policy Terms and Conditions.