© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

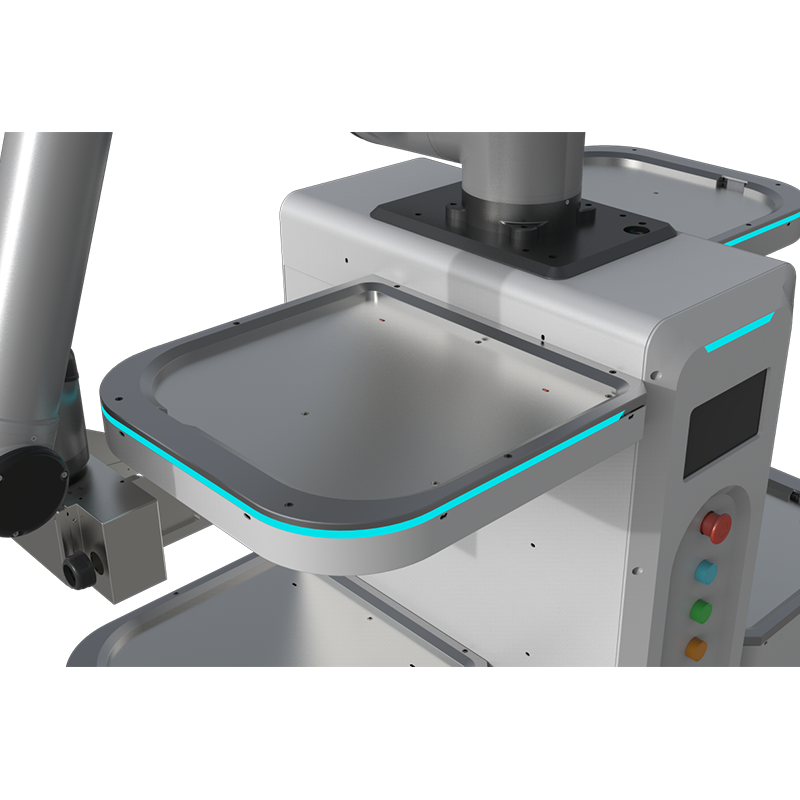

The semiconductor industry is increasingly relying on automation solutions to meet the rising demands for efficiency and precision. Transforming the way semiconductor manufacturers handle the loading and transporting of 12'' Foup pods, the Youibot OW12 is a pioneering mobile manipulator robot. This article delves into the OW12's many benefits, showcasing its technological advancements and practical uses.

Unmatched Navigation and Flexibility

The Youibot OW12 distinguishes itself with its high-performance mobile laser navigation chassis. This advanced feature not only allows the mobile manipulator robot to navigate complex environments but also ensures it can adapt to changing layouts and workflows. The OW12's ability to maneuver smoothly through tight spaces enhances operational efficiency, enabling manufacturers to optimize their facility layouts without sacrificing productivity.

Moreover, the incorporation of a flexible collaborative robot (cobot) makes the OW12 exceptionally versatile. Unlike traditional industrial robots, which often require extensive programming and setup, the OW12 can be easily reconfigured for various tasks. This flexibility allows manufacturers to respond quickly to production changes or unexpected challenges, a crucial advantage in the fast-paced semiconductor industry.

Prioritizing Safety and Cleanliness

In semiconductor manufacturing, safety and cleanliness are non-negotiable. The Youibot OW12 is equipped with LiDAR technology that provides comprehensive safety detection, both horizontally and vertically. This ability to detect obstacles enhances workplace safety, reducing the risk of accidents and ensuring a secure environment for employees and equipment alike.

Additionally, the OW12 meets cleanliness standards up to Class 100, which is vital for maintaining the integrity of semiconductor products. By automating the loading and transferring processes, the mobile manipulator robot minimizes human interaction with sensitive materials, significantly reducing the risk of contamination. This dual focus on safety and cleanliness positions the OW12 as a reliable solution for manufacturers striving to maintain high-quality standards.

Elevating Operational Efficiency

The introduction of the Youibot OW12 marks a significant shift in how semiconductor manufacturers approach automation. By streamlining the loading and transferring of Foup pods, this mobile manipulator robot helps reduce cycle times and improve overall productivity. The automation of these critical tasks allows human operators to focus on more complex activities that require higher-level decision-making and problem-solving skills.

Furthermore, the OW12’s integration into existing production lines is relatively seamless, thanks to its intuitive design and user-friendly interface. This ease of integration minimizes disruption during implementation, allowing manufacturers to quickly reap the benefits of enhanced efficiency.

Conclusion

The Youibot OW12 is not just another piece of equipment; it represents a paradigm shift in semiconductor manufacturing. As companies seek to enhance their operational capabilities while ensuring safety and cleanliness, the OW12 stands out as a leading mobile manipulator robot that meets these demands. With its innovative navigation system, flexible cobot functionality, and adherence to cleanliness standards, the OW12 is poised to redefine automation in the semiconductor industry. Embracing such advanced technology is crucial for manufacturers aiming to remain competitive in a rapidly evolving market. The future of semiconductor manufacturing is here, and it is embodied in the Youibot OW12.

By continuing to use the site you agree to our privacy policy Terms and Conditions.