© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

Autonomous mobile robots (AMRs) are revolutionizing the way materials are transported in the industrial logistics. AMRs are equipped with sensors and mapping technology that enable them to navigate autonomously within a facility. This eliminates the need for human intervention, resulting in improved productivity, safety, and efficiency. In this blog post, we will explore the various applications of AMRs in industries such as 3C electronics, semiconductors, automotive, display panels, and lithium-ion batteries.

The 3C electronics industry requires the transportation of components and finished products within a warehouse or factory. AMRs can be used to transport these items autonomously, which reduces the need for manual labor and increases productivity. The robots can navigate through narrow aisles and around obstacles using sensors and mapping technology. Additionally, AMRs can improve order fulfillment times by delivering products to their designated locations quickly.

In semiconductor manufacturing, AMRs can transport materials such as silicon wafers and chemicals between various stages of the production process. These materials are often delicate and require careful handling to prevent contamination or damage. AMRs can operate within a cleanroom environment without introducing contaminants, improving product quality and reducing the risk of defects.

The automotive industry requires the movement of heavy components such as engines, transmissions, and chassis. AMRs can be used to transport these components around the factory floor, allowing workers to focus on more skilled tasks. The robots can also work collaboratively with humans, increasing overall productivity.

Display panel manufacturing involves the movement of large glass substrates, which can be fragile and difficult to handle manually. AMRs equipped with specialized grippers can transport these substrates safely and efficiently, reducing the risk of damage and increasing throughput. The robots can also be programmed to avoid collisions with other equipment or workers in the facility.

The lithium-ion battery industry requires the transportation of heavy and hazardous materials. AMRs can transport these materials safely and efficiently, reducing the risk of accidents and injuries. Additionally, the robots can move finished products to storage areas or shipping docks, improving overall productivity.

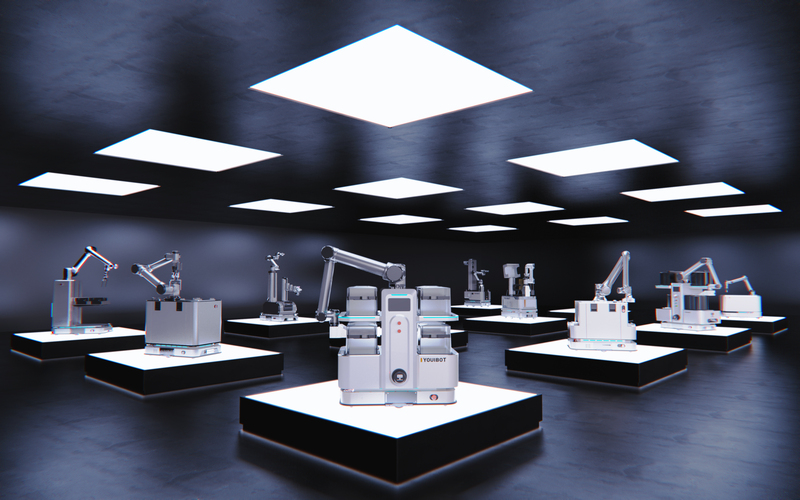

the development of robotics technology has revolutionized the way businesses operate in various industries. With its core focus on robot research and development, Youibot Robotics is at the forefront of this transformation.

If you're interested in learning more about Youibot Robotics and how our intelligent automation solutions can benefit your business, please visit our website at www.youibot.com. Our team of experts is always available to assist you with any queries or requests for a consultation.

By continuing to use the site you agree to our privacy policy Terms and Conditions.