© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

In recent years, with the acceleration of digital transformation in traditional industries, IDC computer room-scale has ushered in explosive growth driven by national policies and technological development. At the same time, the industry as a whole is moving towards intelligence, visualization and modularization.

Issued by the State Council in February this year"Guiding Opinions on Accelerating the Establishment and Improvement of Green and Low-carbon Circular Development Economic System" pointed out that it is necessary to accelerate the green transformation of the information service industry, do a good job in the green construction and transformation of large and medium-sized data centers and network computer rooms, and establish a green operation and maintenance system. As an emerging infrastructure for the development of the digital economy, improving IDC's operation and maintenance level, improving business reliability and enhancing decision-making capabilities have become the main development trend.

The intelligent data center inspection solution created by Youibot for IDC can efficiently perform digital data center inspection, improve inspection efficiency and accuracy, ensure stable and efficient operation of data centers, and help IDC upgrade its green intelligence.

During the World Artificial Intelligence Conference from July 7 to 10, 2021, Youibot Intelligent Computer Room Inspection Solution will be unveiled at the exhibition site!

AI redefines data center O & M.

Youibot Intelligent O & M Solution

At present, the construction cycle of a large-scale IDC is about 1-2 years, which is usually located far away from the urban area. It is difficult to recruit and costly for daily inspection, operation, and maintenance personnel, and the flow of personnel is large. There are problems such as less inspection and missed inspection in the process of manual inspection, and there is a lack of data management and utilization.

In the context of carbon neutrality becoming the mainstream trend of industry transformation, PUE as an indicator to measure the energy efficiency level of data centers is the focus of all parties. Taking the "Guidelines for the Construction of Shanghai Data Centers (2021 Edition)" as an example, it is required that the integration of PUE for new large-scale data centers should not exceed 1.3, while the average PUE for traditional IDC is 1.54 to 1.63, and the energy consumption is generally large.

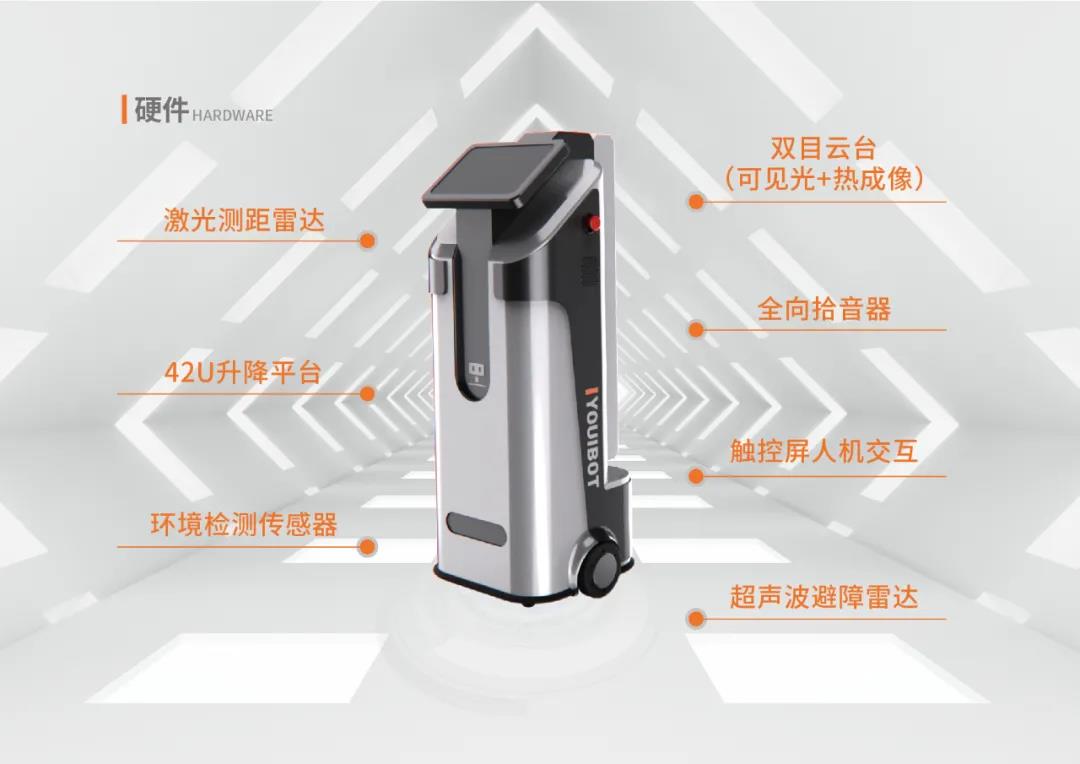

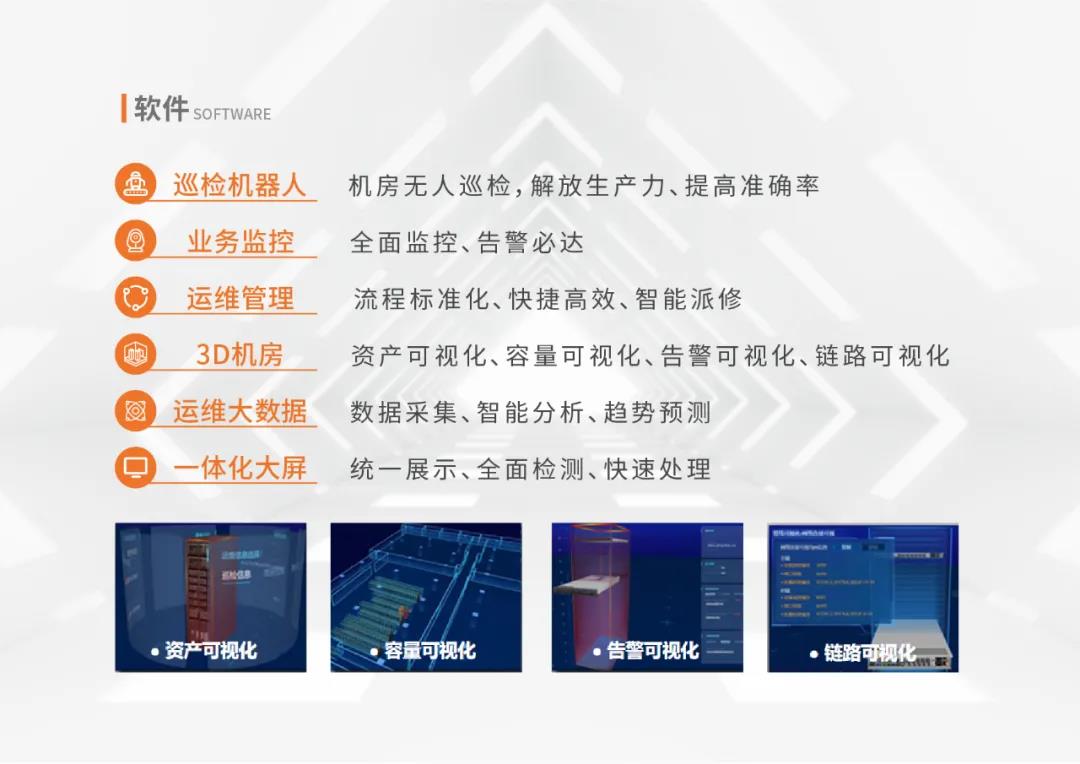

To address the difficulties and difficulties faced by IDC inspections, such as manpower gaps, missed inspection risks, and high energy consumption, Youibot Mobile Intelligent Inspection Robot Independent inspection, intelligent analysis, and rapid fault location in the data center can improve the efficiency and accuracy of inspection, ensure the stable and efficient operation of the data center, and assist the data center to optimize resources and reduce energy consumption, thus realizing green transformation and upgrading.

AI main deep learning machine vision algorithm

Based on the edge intelligent computing platform, the inspection machine of Youibot computer room can conduct in-depth AI master learning. With the cooperation of the machine vision algorithm, the intelligent inspection machine monitors and learns and accumulates the indicator lights, instrument panels, liquid crystal panels, switches and other components of the cabinet through the camera during each inspection, and continuously improves the recognition accuracy. when the equipment is found to be abnormal, the machine room inspection machine will notify the operation and maintenance staff through background alarms, text messages, emails, etc. at the first time, and guide the operation and maintenance staff to the corresponding cabinet for processing.

Temperature and humidity detection: mainly detect the temperature and humidity in the machine room to ensure the operation of the equipment in the machine room under the condition of meeting the standards.

Noise detection: It mainly detects the noise of servers and fast-running equipment in the machine room, and detects the operation of hardware equipment in real-time.

Odor Detection: It mainly detects the volatilized smoke and toxic agents of cables and wires before combustion, and prevents corruption caused to hardware equipment in advance, especially servers in computer rooms, UPS power distribution cabinets, etc.

Air-to-air quality inspection: It is mainly used to detect the dust concentration in the air-to-air in the machine room, reduce the insulation performance of circuits and components and corrode the circuit board, shorten the life of the equipment, prevent blockage and dust prevention, and affect the heat dissipation efficiency of IT equipment.

Full alert: Realize real-time monitoring, fault management, performance analysis, and configuration optimization of IT infrastructure from daily operation and maintenance, fundamentally ensure the healthy and stable operation of the business, further improve the operation quality of the network support environment, and use effective maintenance methods to provide strong support and technical support for business development.

Asset inventory: The visual inventory task of equipment is in the mode of inspection and inventory every time. It mainly focuses on the abnormal removal of equipment. When changes are found, the machine and the software platform link up to send out sound and light alarms and notify the operation and maintenance staff in time to form an inventory data report.

face-holding identification verification, prohibition control, interaction with six grams of machines, guiding staff to enter the designated workplace, fixed-point language explanation function, and online real-time intercom function.

Helps upgrade IDC green intelligence

The inspection efficiency and accuracy are greatly improved.

Optimize PUE to Reduce Carbon Emissions

Real-time monitoring of important parameters such as temperature and airflow in the computer room and sending them back to the management system, all-round scanning and positioning of "hot spots" to accurately cool down, assist the computer room to reasonably adjust and optimize the configuration of the refrigeration system, so that the computer room always maintains the optimal operating environment, thereby reducing PUE and carbon emissions.

Mobile Enabling New Infrastructure

With the wave of "new infrastructure", 5G, cloud computing, and other technology development in the fast lane, the digital industry economic development is at the right time.

As a leading provider of mobile robots and solutions in China, Youibot through the integrated intelligent inspection solution, the automation, and intelligence of operation and maintenance management are improved, which greatly helps the construction of new infrastructures such as big data centers and rail transit.

In addition, based on an integrated intelligent manufacturing solution, with semiconductors as the core, Youibot has formed an on-site logistics layout covering the entire industry chain of precision electronics manufacturing, opening up the on-site material flow and data flow, and helping enterprises achieve stable, continuous, and efficient production.

At present, the domestic market of Youibot covers 23 provinces (municipalities and autonomous regions), and its products are exported to more than 30 countries such as Japan, South Korea, Singapore, Spain, Germany, and Italy. It is in precision electronics manufacturing, power plant inspection, large warehouse inventory, and wisdom. He has accumulated rich scene experience in vertical fields such as archives and has become a partner of many well-known brands at home and abroad, such as CRRC.

Youibot actively implements the corporate mission-"Robot Technology Enabling Scenario Change", through continuous technological innovation and scene innovation, to help the intelligent upgrading of the industry.

By continuing to use the site you agree to our privacy policy Terms and Conditions.