© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

On March 17, the 2021 Munich Shanghai Electronic Production Equipment Exhibition, known as the weather vane of China's electronic production and manufacturing industry, kicked off in Shanghai. Nearly 800 high-tech electronic manufacturing enterprises gathered together to jointly demonstrate the cutting-edge technology of China's intelligent manufacturing.

With the advancement of industrial interconnection and intelligent manufacturing, the domestic electronic equipment production model continues to iterate, forming a new pattern of intelligent production led by technological innovation, and promoting the industry to achieve leapfrog development.

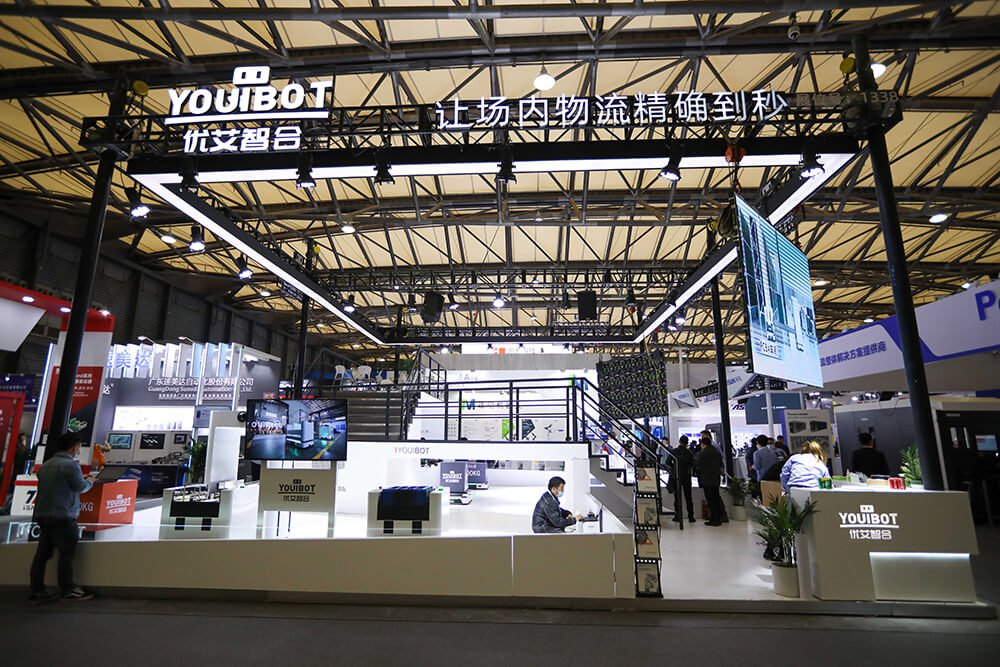

As the leader of composite mobile robots in China, Youibot has created an integrated logistics solution based on mobile robots for precision electronic manufacturing, attracting many visitors to this exhibition.

Multi-in-One Solution Makes Field Logistics Accurate to Seconds

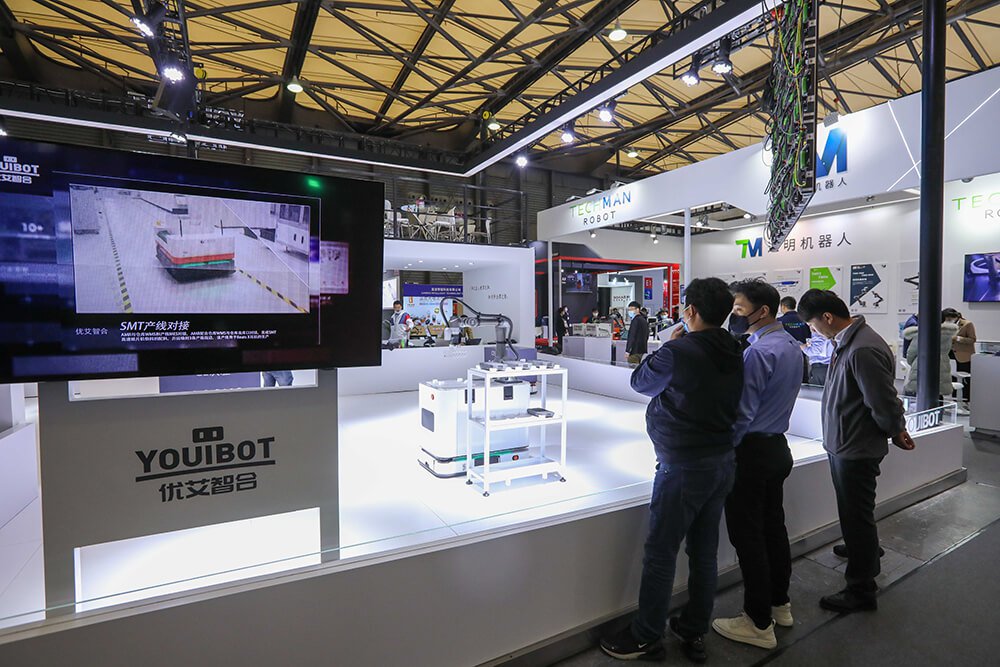

Exhibition area, a mobile robot is using a mechanical arm to accurately grab and autonomously transmit the material box on the shelf, while the roller robot on the other side is automatically loading and unloading materials. Corgi and Trans, the robots shuttling between the exhibition areas, are responsible for the task of material operation, supporting 200KG and 1000KG loads respectively. The accuracy of natural navigation (no auxiliary positioning) reaches 2mm,250mm-1100mm docking height material transfer requirements, and can automatically transfer materials between different production lines and processes.

These robots are uniformly scheduled and managed through the logistics scheduling system of Youibot. 300 hybrid robots can be scheduled in the scene, with multiple functions such as cross-floor and material management. Under the control of the dispatching system, the mobile robot not only realizes the precise loading and unloading of materials and efficient transportation, but also flexibly adapts to the adjustment of the production line and the change of the pattern, and conforms to the demand of electronic equipment expansion under the rapid development of the industry.

The whole process of intelligent production and breaking the "information isolated island" of each link of equipment is the key. Youibot has built a YouiTMS intelligent logistics system on the basis of mobile robots, and upgraded the automatic flow of mobile robots between processes to data connection, which not only ensures the efficient operation of the entire production line, but also interacts with the manufacturing management system to achieve Error prevention, traceability and other functions complete the data closed loop of the entire production life cycle.

This is the most efficient and flexible automated logistics solution in the discrete dynamic production mode on the market,are independently developed by Youibot Robot.

Mobile robot is equipped with a multi-machine scheduling management and control system and an intelligent logistics management system, covering the logistics in the entire production cycle of the factory, completing the unmanned operation of the entire process of production materials from the raw material warehouse to the production lines, and then to the finished product warehouse, and truly opening up the factory the material flow and information flow in the company help companies achieve the goals of improving quality and efficiency, flexible production, and digital management.

Multi-point Enabling Industry Upgrade with Burst in Demand for Composite Robots

"14th Five-Year Plan" points out that it is necessary to further implement the strategy of manufacturing power and promote the optimization and upgrading of the manufacturing industry.

"In recent years, high-end electronics manufacturing capacity has been shifting to the domestic market, and the overall scale of China's electronics manufacturing industry has continued to grow at a high speed. At the same time, the industry is transforming from local automation and informatization to full automation and intelligence." Xu Yan, director of intelligent manufacturing products at Youibot, said.

He pointed out that some labor-intensive and complex tasks urgently need to be replaced by automation technology. At this time, the value of composite collaborative robot technology is prominent, especially in the electronic manufacturing industry with relatively complete automation and informatization. Youibot integrates mobile robots with logistics management and control systems and has provided intelligent workshop logistics upgrade services for a large number of well-known precision electronic manufacturing enterprises such as semiconductors and components.

Introduced the integrated logistics solution of Youibot to realize the full automation of logistics operations such as material frame handling and circulation, and the digital management of the entire production process. The efficiency of the factory has been improved by about 30%, the material handover and transportation are accurate and efficient, the product yield has been greatly improved, and the rapid transformation and deployment have shortened the shutdown and transformation cycle, saving a lot.

Precision Manufacturing is one of the business layouts of Youibot. As a leading composite mobile robot enterprise in China, Youibot is helping global enterprises to realize the multi-domain intelligent upgrade of manufacturing, patrol operation and maintenance scenarios through the overall solution of mobile robot software and hardware.

"At present, the demand for informatization and intelligent upgrading of large-scale infrastructure, public places and industrial production in China is urgently increasing. In industrial production, Youibot's intelligent composite cooperative robot logistics system has been applied in various industries such as semiconductors, panels, electronic components, and 3C manufacturing. In addition, the company's intelligent inspection solutions based on 5G and AI technology have been applied in all aspects of power generation, power transmission and transformation, and data centers in the energy industry. More and more companies have benefited from completing intelligent upgrades through mobile robots. Become the mainstream trend in the process of industrial automation." Xu Yan introduced.

By continuing to use the site you agree to our privacy policy Terms and Conditions.