© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

The market for autonomous mobile robots (AMRs) is booming, and multinational manufacturers across the supply chain are incorporating these flexible, collaborative robots into their overall warehouse automation strategies. Previously, employees had to push carts around the facility, however, now this task is performed by autonomous mobile robots, realizing the automation of material handling and internal transportation tasks easily, efficiently, and cost-effectively in almost any situation. Here are the answers to the questions we receive the most from our potential clients.

AMRs are collaborative and designed to work with human beings. The main feature of these collaborative mobile robots is that they are extremely safe and work in dynamic environments alongside humans. If someone stumbles in front of the AMR, the safety laser scanning system will quickly detect the obstacle and then change its direction or completely stop to avoid the collision.

Companies in the supply chain are integrating mobile robots into applications that require the transportation of various materials or products. Robots can be part of a fully automated fleet, delivering goods to between warehouses or between production workshops and warehouses. AMRs is easy to be programmed and integrated into all types of indoor environments, including places with more challenging dynamic plants.

Unlike automated guided vehicles (AGVs), which must be guided by cables, magnetic strips, or sensors installed in warehouses, AMRs move through maps constructed by software in the field, laser scanners, or pre-loaded facility drawings. It is very similar to a car with GPS in which a series of maps are previously loaded. The system determines the best route as you move from one point to another. AMR is instructed to store locations, and collect and deliver products through its intuitive interface. AMRs use data from integrated cameras, sensors, and laser scanners, as well as sophisticated software, to detect their surroundings and choose the most efficient route to their target. It works completely autonomously, and if there are forklifts, pallets, people, or other obstacles ahead, the AMR will safely bypass them, using the best alternative route.

Th fact that the ease of integration and the company does not need to make any changes to the factory layout ensures the low initial costs. Additionally, AMRs are a reliable workforce as they can last 12 to 15 hours without interruption. When they have no tasks, they can be loaded automatically, ensuring smooth work and optimizing internal logistics. A robot usually frees up two full-time employees who can devote themselves to more valuable tasks.

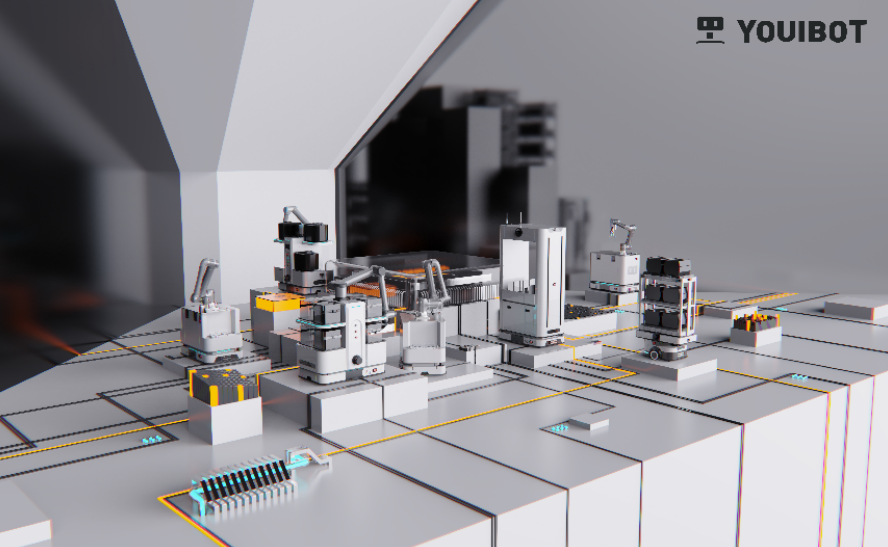

Youibot Robotics has accumulated rich experience in intelligent logistics in vertical fields such as power plant inspection, vehicle maintenance, automobile, and semi-conductor industry intelligence manufacturing, become a partner of many well-known domestic and foreign brands.

If you have any more questions about AMRS, please feel free to contact us.

By continuing to use the site you agree to our privacy policy Terms and Conditions.