© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

Original: Zhang Chaohui, CEO of Youibot

In the opening chapter, the richness of mobile robot landing scenarios is mentioned. The recent outbreak has brought fire to a wave of service robot applications, and I also talked about our anti-virus robot at the beginning of the previous article, and the thinking logic of this commercial application. In this article, I want to start from industrial applications, that is, the second half of the previous article, in the scenario of intelligent manufacturing and intelligent operation and maintenance, How to quickly build a mobile operation robot and form a closed loop.

Industrial AMR

Intelligent manufacturing has been a hot topic in recent years. In the previous article, there were three stages of intelligent factory construction. Material flow-> information flow-> decision flow. Today, we will start from the material flow and see how mobile operating robots and industrial AMR can connect the physical connection and information connection of factory construction.

Industrial AMR? What industrial-grade needs is high precision, high stability, and high safety, different from service level, industrial AMRHardware Selection, including motors, battery, driver, radar, regulated power supply, PLC, even wheels are industry standards, and then security policies, and the software, are more stringent requirements. Because in the industrial site, once out of control, the consequences are disastrous, there can be no slack.

The industry will quickly lead to the second problem, that is, non-standardization. 3C, semiconductors, automobiles, auto parts, aircraft manufacturing, and other scenarios are different, and even different processes in each scene are different. Therefore, responding quickly according to the changes in the scene is very essential.

[It is very important to grasp the change and change of the scene]]

Lao Zi said, "Tao gives birth to one, one life two, two gives birth to three, and three gives birth to all things". The same is the law, the change is only a phenomenon. Taking what we have done as an example, we think about most of the commonalities in industrial logistics, which should start from mobile robot control systems and multi-machine scheduling and management systems, as well as standard hardware.

1. From the robot system level, build a standard mobile robot positioning and navigation system YouiPilot are laser non-reverse, laser anti-reverse, and QR code. Among them, the most important is the laser non-reverse positioning in the navigation mode with, stable docking accuracy of 5mm. The following figure is a laser map of our facilities in an energy enterprise. There are 688 task points in total. It is necessary to ensure the high-precision positioning of each task point in order to accurately realize the task of each point.

2 million square meters, 688 mission points

2 million square meters, 688 mission points

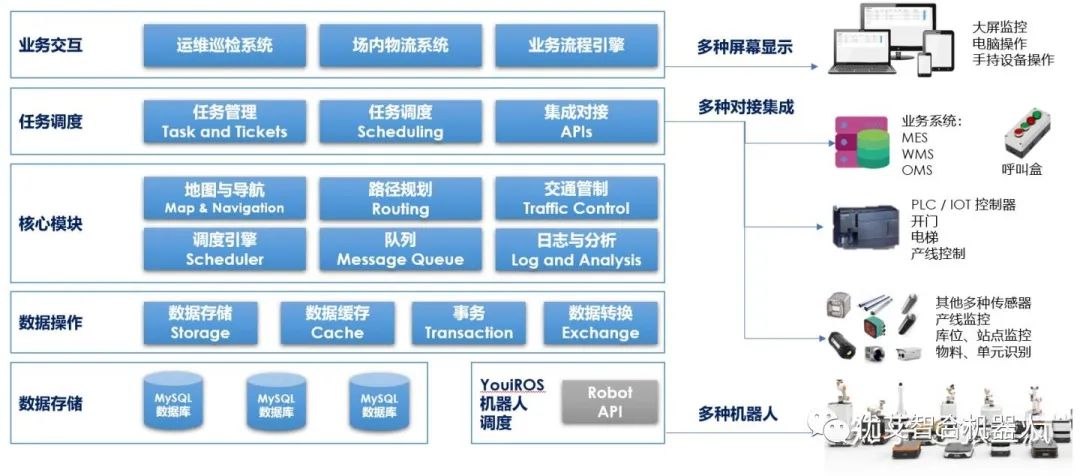

2. From the business system level, build a configured business process engine, on-site logistics system, operation, and maintenance inspection system YouiFleet

, we can see that in the process of landing and using the robot, it is far from being satisfied with moving the robot from point A to point B, but it really connects the robot and the system. From the link, there will be MES, ERP, and WMS. I think in the industry of mobile robots, everyone talks about how the car body is doing every day, SLAM is not high in precision, which is wrong. When we serve our customers, we think that this is the most basic thing that every robot company that enters laser navigation must do. The robot's brain should not be a stand-alone positioning and guidance system but should be truly able to achieve business connection, carrying out order splitting, merging, and dispatching, a scheduling system for intelligent path planning and scheduling decision-making is an on-site logistics system that can drive the rapid connection between plant material flow and information flow. In this sense, this link is as indispensable as MES.

YouiFleet System architecture

YouiFleet System architecture

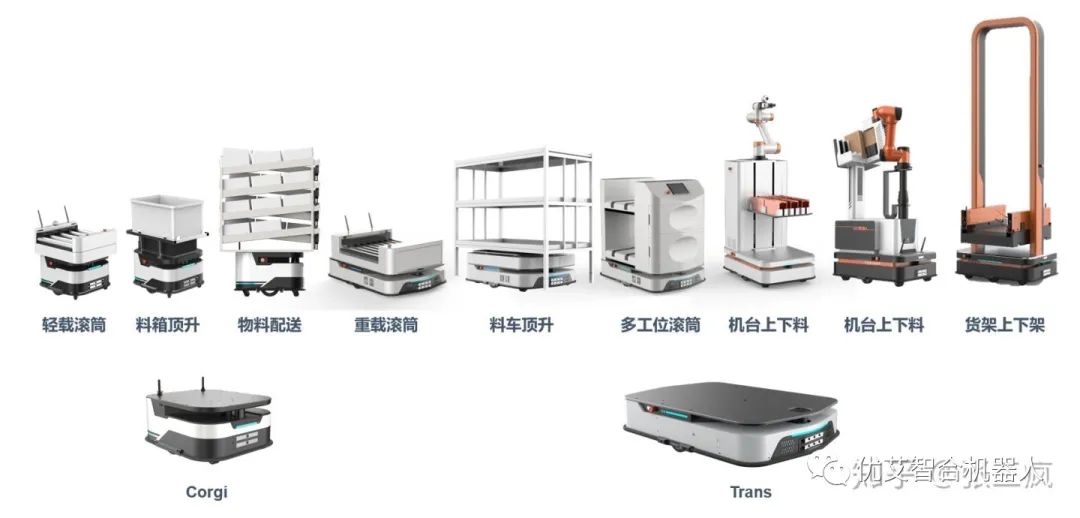

3. To build standard hardware components, Corgi and Trans are two series of standard mobile robots.

We analyzed the constant demand and effectively transferred the materials. We have also seen the application of changes, such as rollers, lifting, loading and unloading, and loading and unloading. Therefore, we tried to split it. Corgi is light load level, passability, width is only 500mm,100kg, Trans is medium load level, universal type, top plate height from the ground is only 200mm, which should be the flattest chassis I have ever seen in the whole industry, and 200kg-1000kg. Therefore, different organizational structures have emerged, and the corresponding scenarios are changing.

Corgi and Trans Series Mobile Robots

Corgi and Trans Series Mobile Robots

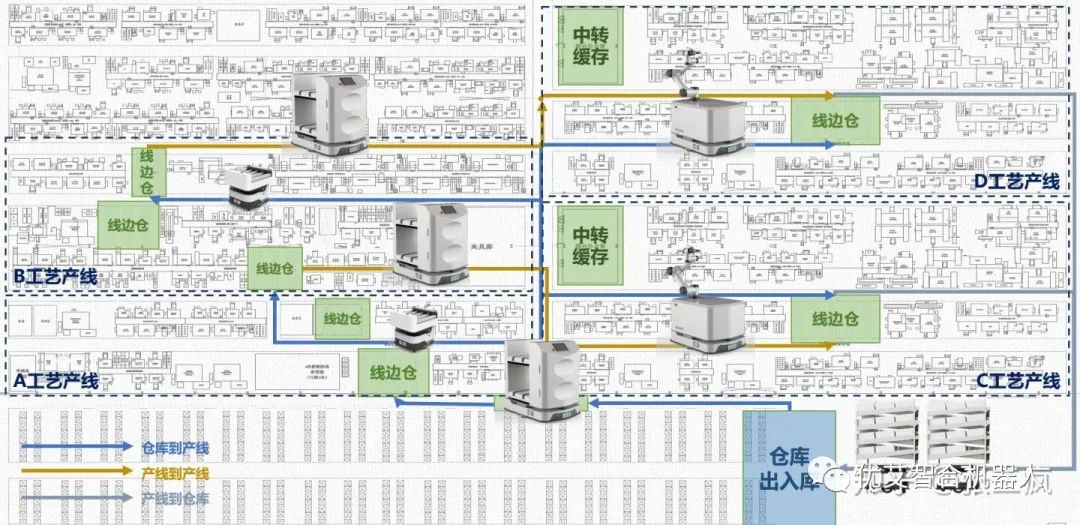

The mobile operation robot application completed by combining software and hardware can be quickly generated.

Youiboton-site logistics system

Youiboton-site logistics system

The practical application is as follows

Cross-industry robot applications

Cross-industry robot applications

We basically explain our thinking framework for the rapid application of mobile robots in industrial logistics. How to quickly apply standard systems and standard mobile robots requires continuous exploration.

look forward to exploring with you!

By continuing to use the site you agree to our privacy policy Terms and Conditions.