© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

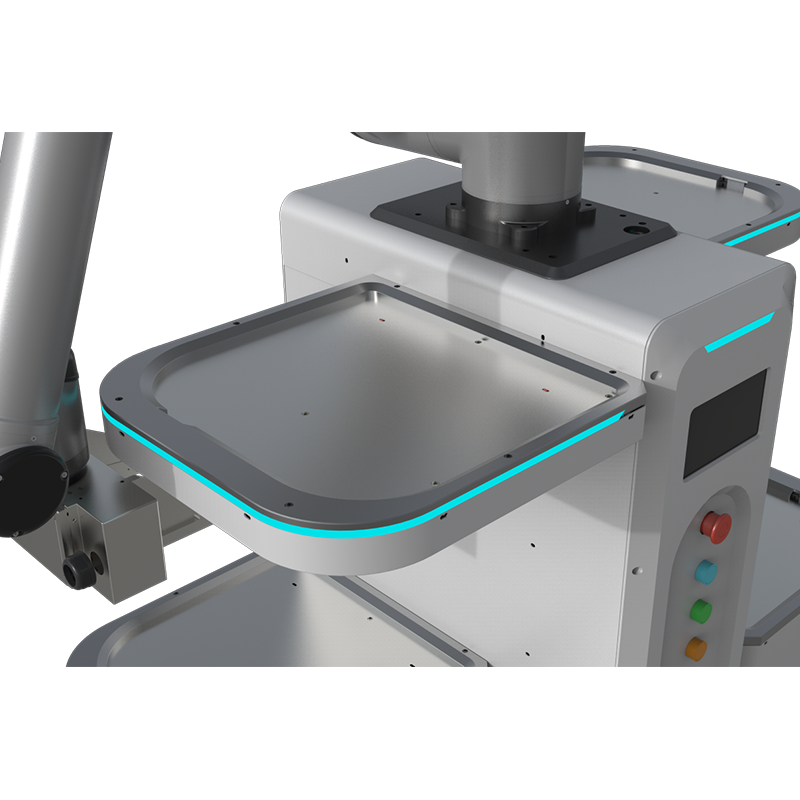

In the fast-evolving world of semiconductor manufacturing, automation plays a critical role in enhancing efficiency and maintaining stringent quality standards. Youibot's OW12 mobile manipulator robot emerges as a game-changer in this sector, designed specifically to meet the unique demands of loading and transferring 12'' Foup pods. This blog explores the innovative features of our Youibot's OW12 and how it stands out as a pivotal tool in semiconductor manufacturing automation.

Advanced Design and Functionality

High-Performance Mobile Laser Navigation Chassis

At the heart of the OW12 is its high-performance mobile laser navigation chassis. This sophisticated system allows the robot to navigate complex manufacturing environments with precision and ease. The laser navigation not only ensures accurate positioning but also enhances the speed and efficiency of the robot's operations, making it an invaluable asset in high-paced production settings.

Flexible Collaborative Robot (Cobot)

The OW12 is equipped with a flexible cobot, engineered to work safely alongside human operators. This cobot is designed for delicate tasks, such as handling and transferring sensitive semiconductor pods without compromising their integrity. Its flexibility allows it to adapt to various tasks required in semiconductor manufacturing, providing a versatile solution to automate complex manual processes.

Enhanced Safety with LiDAR Technology

Horizontal and Vertical Safety Detection

Safety is paramount in any manufacturing setting, and the OW12 addresses this with its integrated LiDAR technology. This system provides horizontal and vertical safety detection, creating a safe working environment by preventing collisions and ensuring the robot operates within safe parameters. This technology not only protects the equipment and human operators but also ensures uninterrupted production flow, crucial for maintaining productivity levels.

Compliance with Industry Standards

Cleanliness up to Class 100

The semiconductor industry requires environments that adhere to strict cleanliness standards to prevent contamination that could lead to product defects. The OW12 meets these rigorous standards with a design that maintains cleanliness up to Class 100. This feature is particularly vital in semiconductor manufacturing, where even minute particles can compromise the quality of the chips being produced.

Conclusion

Youibot's OW12 mobile manipulator robot is tailored to tackle the challenges of semiconductor manufacturing. By combining advanced navigation technology, a flexible robotic arm, and stringent safety features, the OW12 not only enhances operational efficiency but also elevates the standards of safety and cleanliness required in the industry. Its ability to seamlessly integrate into existing production lines and its compliance with critical industry standards make it an essential tool for companies aiming to advance their manufacturing capabilities and maintain a competitive edge in the market.

As the semiconductor industry continues to expand and evolve, the OW12 stands ready to meet its growing demands, proving that smart automation is key to achieving greater productivity and reliability in high-tech manufacturing environments.

By continuing to use the site you agree to our privacy policy Terms and Conditions.