© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

At Youibot, we have proudly embraced this challenge, developing a range of state-of-the-art automated mobile robot solutions that are redefining the landscape of material handling. In our pursuit of innovation, we have meticulously engineered our AMR solutions to meet the diverse needs of different industries. Recognizing that no two businesses are the same, we have developed a range of customizable AMR solutions that can be tailored to specific requirements. Whether it's automating the movement of goods in a warehouse, optimizing logistics operations in a distribution center, or enhancing material flow in a manufacturing facility, our AMR solutions are designed to address the unique challenges faced by businesses across various sectors.

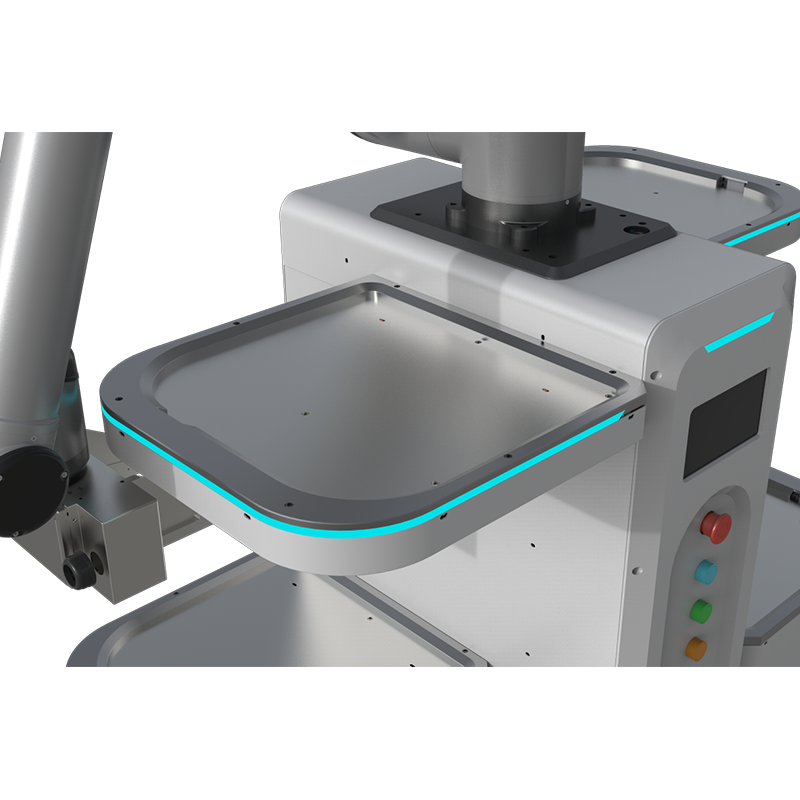

One of the crown jewels in our automated mobile robot portfolio is the Youibot OW12, a specialized solution designed to meet the unique requirements of the semiconductor manufacturing industry. Equipped with a collaborative robot (cobot) and advanced vision sensors, the OW12 is engineered to handle and transport 12-inch FOUP (Front Opening Unified Pod) containers with unparalleled precision and efficiency. The precise and efficient handling of 12-inch FOUP containers is crucial in the semiconductor manufacturing process, as these containers house and protect delicate wafers. The OW12's engineering excellence ensures that the handling process is carried out flawlessly, minimizing the risk of damage or contamination to the wafers.

It's the Youibot OW12 that's revolutionizing semiconductor automation. The OW12 is made with an end gripper and vision sensor that can precisely grasp the containers at the upper clamping fixture, minimizing direct contact with the delicate FOUP PODs. This reduces the vibration impact on the PODs.

This creative method lowers the possibility of harm and guarantees uniformity in the manufacturing workflow while simultaneously improving the material handling process's safety and dependability. The OW12 is the perfect robotic option for automated material handling since it satisfies the strict criteria needed in the semiconductor industry with a vibration rating of less than 0.5G for flat ground operation.

As the world of industry continues to evolve, the integration of automated mobile robots has become a critical component of success. Our solutions for AMRs offer unparalleled flexibility and adaptability. They seamlessly integrate into existing workflows and can be easily reconfigured to handle various types of materials and environments. Whether it's a warehouse, manufacturing facility, or distribution center, our AMRs navigate complex spaces, efficiently avoiding obstacles and optimizing travel routes. This flexibility allows businesses to quickly adapt to changing market demands, scale their operations, and stay ahead of the competition.

By continuing to use the site you agree to our privacy policy Terms and Conditions.