© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

: Geek Park

The original link:http://www.geekpark.net/news/225115

Huaqiangbei road is a magical place. You can assemble an iPhone for 1500 yuan, and you can often get the rumored flagship mobile phone model in advance. The electronic manufacturing industry is booming here, and the products made are delivered to all parts of the world, making it full of vitality.

It is also a gathering area for makers, because of the convenient conditions for going to sea, mature industrial links, and abundant resources. China, the United States, Japan... If any creative guest with ideas wants to realize his own ideas, this is an excellent area. From ideas to products, this area, which is 930 meters long from north to south and 1560 meters wide from east to west, contains all the necessary links. Creators have become the engine of Huaqiang North's development, while Huaqiang North has become the power to boost Shenzhen.

On December 15, HAX, the world's largest hardware startup accelerator, was on a roadshow in Huaqiang North. I saw unique creative displays from creators from all over the world. They started from practical problems and used different ideas to solve these problems. In particular, some products that deal with actual scenes through AI technology are even more small and big, which is worth sharing with you:

China is a country with a large population, public transportation accounts for 40%-60% of the total number of trips. Incomplete statistics show that there are currently more than 500,000 buses on the road in the country, each with 4-10 tires, and 30% of the tires will be pinned every year. 10% of these pinned tires are at risk of a tire blowout. Therefore, tire inspection is particularly important in bus companies, but almost all inspections have been carried out manually in the past, every 3-6 months to enter the factory for a major manpower inspection, is not only time-consuming and labor-intensive but also inefficient.

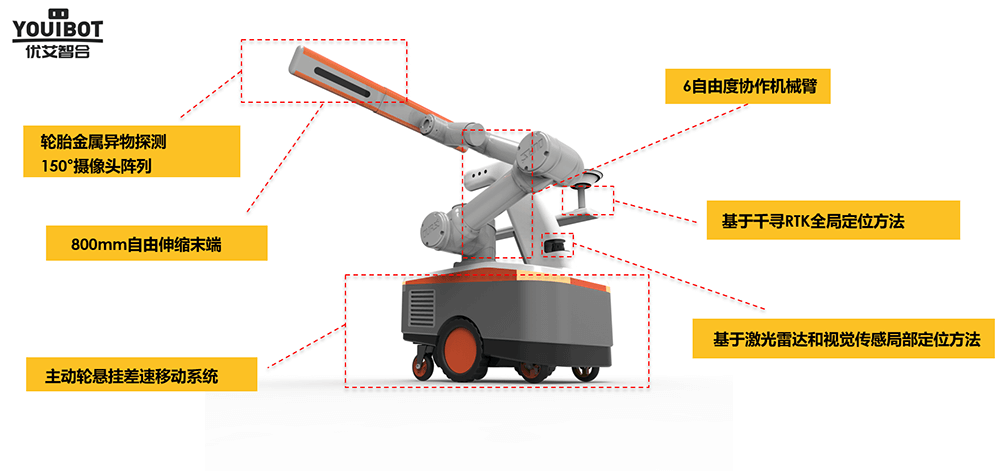

Because of this, when I saw this "tire inspection robot" made by the domestic Youibot and team, many people present brightened their eyes. This robot, which can move at any time, has a robot arm that can rotate freely and retracts. Through the camera array and metal foreign object detector on the robot arm, it can make an all-round inspection around the bus tires, cooperate with the machine vision algorithm to identify whether the tires are pinned or abnormal, and put them into the background database. It only takes less than 2 minutes to thoroughly check a tire, which greatly improves the efficiency at the same time, it also brings changes to car tire inspection that have never been seen in the past.

This team is from Xi'an Jiaotong University. One of the founders, Xu Yan, told me that the reason why they chose such a direction was that they saw the technical gap in tire inspection. At this stage, almost all tire monitoring is done manually. When it comes to periodic testing, factories will queue up. This is a problem that bus companies have encountered. They believe that combining AI technology and robots can solve this problem and improve public transportation. Facts have proved that this attempt is very valuable.

At present, the team has established cooperation with Michelin Company and also plays an inspection role in the factory. Through the built-in RTK global positioning method and lidar of the robot, it can automatically find the way and detect the equipment on the spot. The built-in battery of the machine can work for about 5 hours. Xu Yan told me that this system has already cooperated with Shenzhen Public Transport Company and Beijing Public Transport Company. After sensor modification, this inspection robot can also help customs officers to carry out anti-virus and explosion-proof inspections. In the future, it can also be used for inspection in factories. The application scenarios are very rich.

By continuing to use the site you agree to our privacy policy Terms and Conditions.