© © 2025 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

Promoting the transformation and upgrading of factory intelligence is one of the ways to improve the efficiency of the manufacturing industry.

In a certain the world's leading automobile transmission manufacturer factory, Youibot Smart Logistics Solution has realized the automatic entry and exit of production parts and the handling between production lines, helping the factory to produce stably, continuously, and efficiently, and becoming a model for the transformation of enterprise smarts factories.

As the executor of a major science and technology project in Shaanxi Province, Youibot and the well-known enterprise are working together to promote the research and development of the intelligent production line of the core components of the automobile synchronizer, focusing on the flexible intelligent manufacturing of the core components of the automobile.

YOUIBOT Smart Logistics Solution

# Pain point:

1. Compact production beat: The gearbox gear manufacturing industry has a compact production rhythm and frequent turnover between processes;

2. Low logistics efficiency: The traditional handling mode needs to invest a lot of manpower to meet the production and distribution rhythm, with low logistics efficiency, tight area and high turnover rate;

3. High security risks: The weight of the material is heavy, and there is a potential safety hazard in the manual handling process.

Six customized robots are used in the factory, and YOUI TMS logistics control system and YOUIFleet scheduling system are coordinated to realize intelligent management of parts in and out of storage, transportation between production lines, and docking with automatic production lines.

. Software upgrades that meet industry characteristics

·Seamlessly connect upstream ERP,MES, WMS, and other business systems.

Youibot adopts the latest Trans1000 chassis and Trans1000 won the 2021 German Red Dot Design Award. Through complex sensor information coupling calculation, the reliability and safety of material flow are improved, the load is balanced, efficient and flexible, and there is no need to make redundant changes to the production environment. Shorten the deployment cycle and reduce the time for production line transformation.

Material distribution robot realizes the automatic operation of the material from the warehouse to the line-side material rack and the automatic loading and unloading of the line-side roller line and realizes an efficient intelligent manufacturing logistics distribution system.

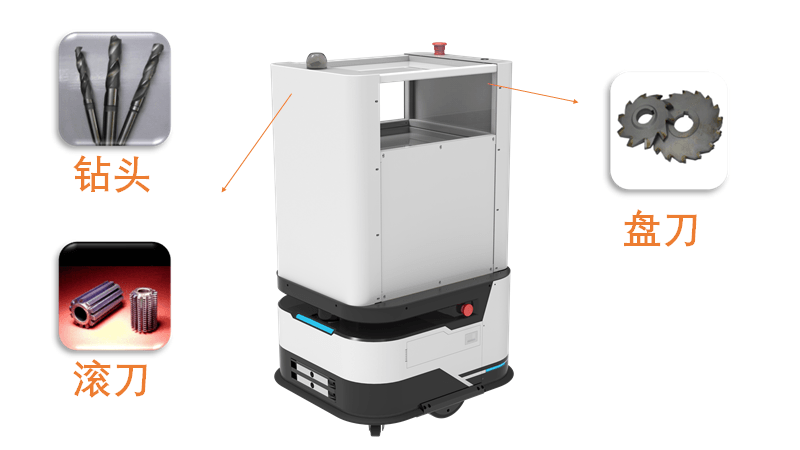

The integrated material rack on AGV can meet the storage of three kinds of tools on site, such as disc cutter, hob and drill bit, and realize automatic distribution from line edge to tool library.

Issue by order

Outbound to the Workbench in strict order.

Improve job efficiency

Tooth hub 4, 5 unit logistics automation process

Adapts to Compact Production Line Station

Through the application of "progressive mode", to meet the beat requirements of inter-line transportation

Digital Management of Warehouse Information

Seamlessly connects the upper-level MES and WMS service systems of the factory to realize digital warehouse management

YOUIBOT Smart Logistics Solution realizes the automation of the process of material distribution, transfer, temporary storage and return of empty appliances in the synchronizer machining part of the production line of the automobile gearbox factory, and ensures a timely, accurate, reliable, and safe logistics process.

After the introduction of Youibot intelligent logistics solutions and other intelligent upgrades, the factory has realized 100% networking of production equipment and automation of production processes and has greatly improved the quality and efficiency of production lines.

By continuing to use the site you agree to our privacy policy Terms and Conditions.