3C Industry Solution

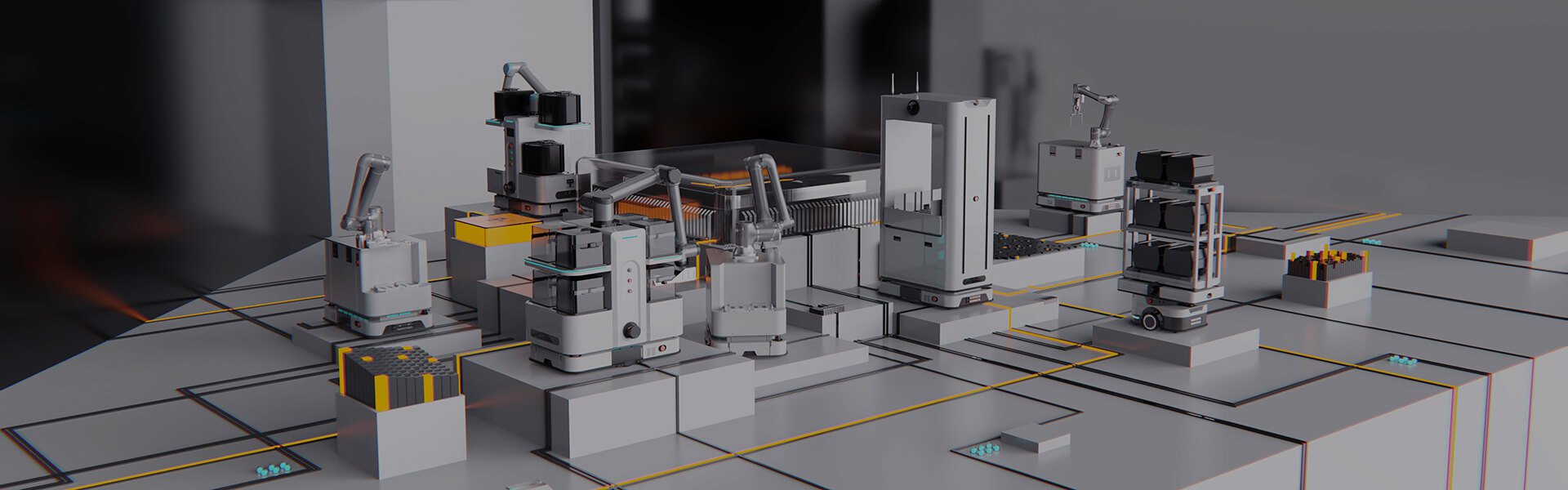

A comprehensive workshop robot logistics solution is configured for handling objects, operating environment, process flow, etc,automatic transfer of materials in warehouses, production lines, line-edge buffers, and machines.

A comprehensive workshop robot logistics solution is configured for handling objects, operating environment, process flow, etc,automatic transfer of materials in warehouses, production lines, line-edge buffers, and machines.

Production equipment is densely arranged,transfer aisles are narrow, and operation space is limited.

The process cycle is frequently updated, and the production layout will change as production process changes.

There are many different types of items in each process section. Both the manual handling efficiency and accuracy are low.

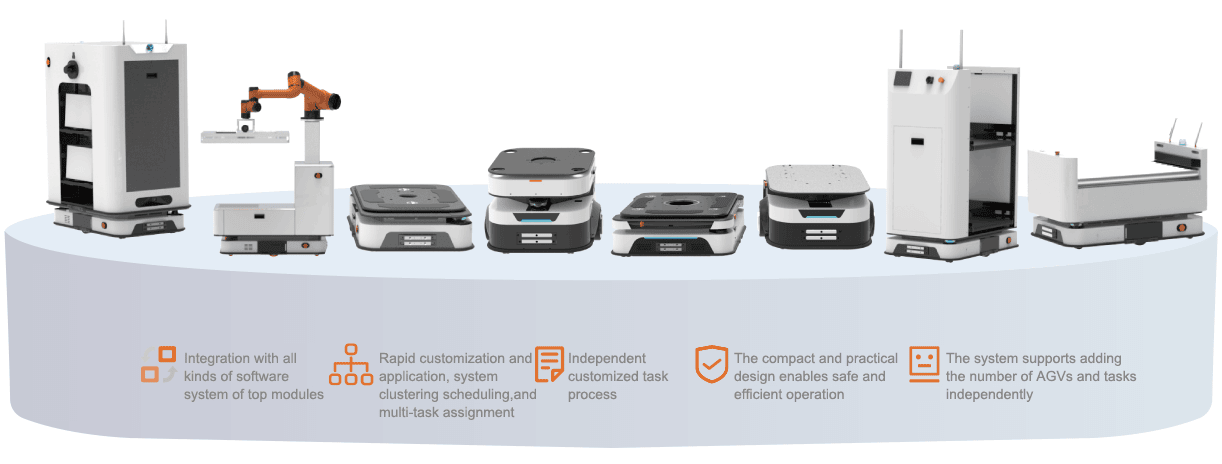

The YOUIFleet intelligent scheduling system manages robots to work for different processes. This system connects multiple robots for communication, task assignment, editing, configuration, execution,etc. The user can flexibly complete the deployment and production use scheduling. YOUIfleet interacts with factory-level MES to achieve timely order arrangement and material transportation.

Intelligent Logistics Management System

Intelligent Scheduling System

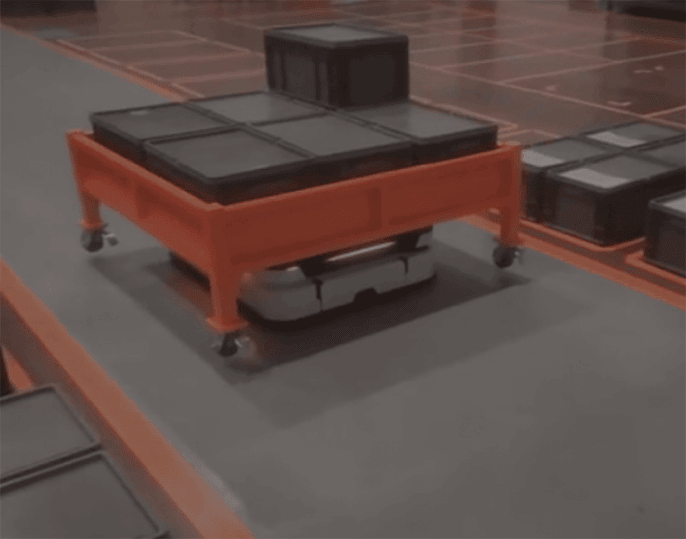

The company is a well-known consumer electronics manufacturer in China. With the compact layout of the production lines and frequent material turnover, it’s difficult for the existing personnel to meet the need of material handling operation after

the production expansion, and the timeliness is hard to guarantee.Therefore, mobile robots are badly in need to complete the logistics operation in the workshops.

In order to better optimize in-plant logistics operation and improve material handling efficiency and quality, the company actively introduces robots for material box transfer so as to realize automation and unmanned in-plant logistics. With the

help of mobile robots with conveyor, the material handling between different production lines and workstations can be fully automated.

Increase work efficiency by 30%

Reduce manual operation intensity by 30%

Convenient transformation and deployment: The robots can easily dock with various devices and adapt to a variety of material handling, shortening the downtime caused by environment and equipment changes

Support 5G network: It supplies the mobile robot with efficient and stable communication network.

The company is a world-renowned provider of smart energy solutions. In the assembly of finished products, the assembled workpieces are heavy, so manual handling has potential safety hazards. The assembly materials cannot be transported in

time, and there are different requirements for cleanliness in different workshops. In order to reduce the involvement of personnel in this process, it introduces the automatic material handling robot solution.

Through the heavy payload mobile robots with rotating & lifting module, together with the YOUIFleet scheduling system and YOUITMS logistics management system, the safety issues incurred by manual pallet jack transportation and declined

cleanliness issue incurred by frequent access to the workshops can be solved.

100% on-time material delivery

Zero safety risk for heavy material transfer

Reduce contamination caused by manual operation

Organized material:

Materials are transported to designated positions. Line-side storage spaces and start positions are neat and tidy.

By continuing to use the site you agree to our privacy policy Terms and Conditions.