IDC Inspection Solution

Our IDC robotics automation adapted to a variety of data centers, the vertical lift inspection robot can be operated for 7*24 hours, and offers one-stop IDC operation and maintenance management.

Our IDC robotics automation adapted to a variety of data centers, the vertical lift inspection robot can be operated for 7*24 hours, and offers one-stop IDC operation and maintenance management.

Manual inspections are intensive and require high skills and responsibility of O&M. Signature records do not have complete traceability.

The standardized implementation of the O&M management mechanism and process system cannot be guaranteed. When a fault occurs, it cannot be quickly located and dealt with timely. It is time-consuming and labor-intensive.

The fixed-point monitoring system equipment interface standards are different and there is a lack of a remote command platform. It is impossible to confirm the on-site situation at the first point of view.

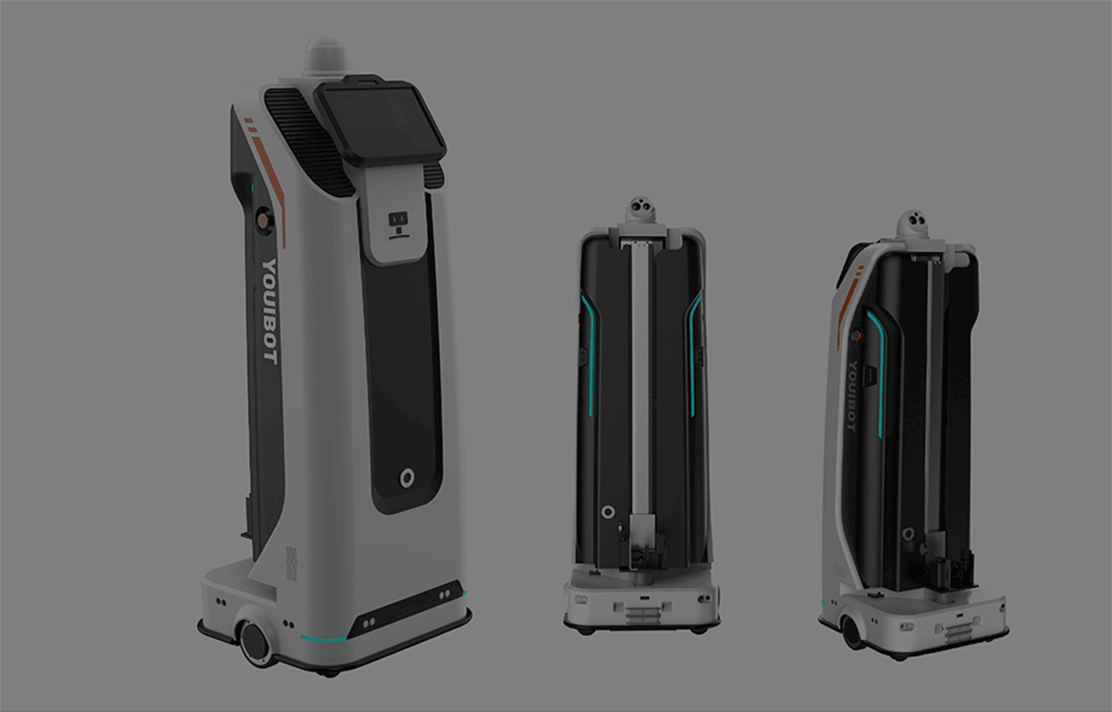

Data Center Inspection Robot

During the inspection process, the combination of HD camera and precise algorithmic logic greatly reduces human error. At the same time, data traceability and accuracy are improved through background logs and records.

The data center robot improves the datamation and informatization of the overall operation. By setting the maintance tasks in advance, it performs inspection work and provides warnings in case of abnormal events automatically. Meanwhile, it informs O&M engineer to deal with them timely to achieve the effect of human-robot collaboration.

The data center robot replaces the repetitive inspection manpower and has great advantages in recognition, perception and notification functions etc. Its compact design and laser multi-modal navigation technology allow it to adapt to narrower and more complex working environments, liberating manpower to do more creative work.

IDC robot inspections involve switching inspection targets at different heights of the same task point and require real-time calculations and give feedback to the background for recording. The data center robot is equipped with a vertical lifting & lowering module, which can well compensate for the defect of insufficient inspection height of ordinary robots. After all inspection standards are determined in advance, the identification accuracy of robot meets 99%.

Inspection Height

Identification Accuracy

MR inspection robot adopts a small-size chassis design, which can adapt to the narrow environment of the site and realize self-leading navigation. Instead of on-site inspection personnel, they are on duty for 24 hours without interruption, monitoring the on-site environment in real time, and issuing fault alarms for abnormal situations.

MR inspection robot integrates a variety of high-tech means such as real-time monitoring of equipment status, multi-sensor fusion, autonomous navigation, intelligent identification, wireless communication, etc. Through the collection and analysis of images, sound, temperature, etc., it completes complex and numerous inspection tasks on site, improves the intelligent level of operation and inspection management, and reduces the labor intensity of operation and maintenance personnel in the computer room.

By continuing to use the site you agree to our privacy policy Terms and Conditions.