Intelligent Logistics Project of a Leading Discrete Device Company in China

Project Overview

The company is a leading discrete device manufacturer in China. YOUIBOT helped the company to upgrade its Semiconductor Manufacturing Workshops, including the automatic loading and unloading as well as material transfer of the

manufacturing equipment at three major processes in workshops.

Solution

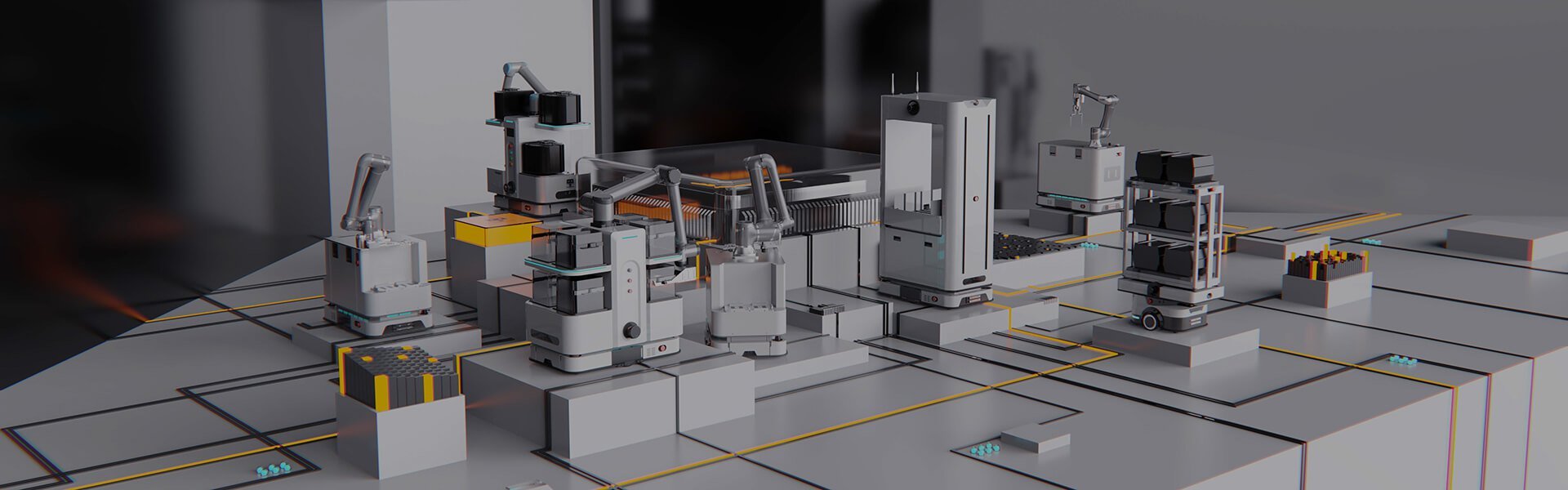

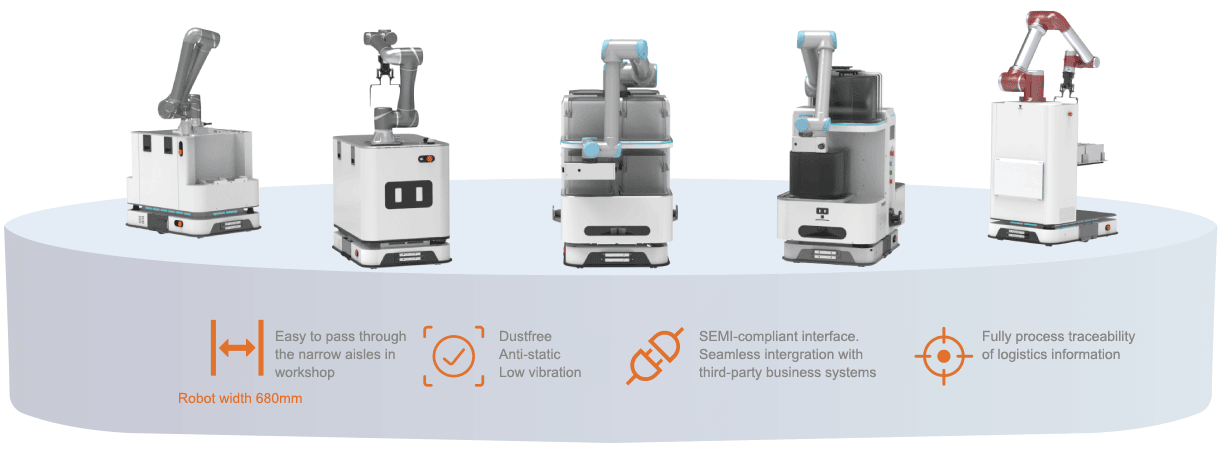

The material transfer system consists of YOUITMS (logistics management system), YOUIFleet (multi-robot scheduling system), and seven mobile robots. The YOUITMS system integrates with the customer's business system to obtain

production orders for scheduling and send the consolidated orders to the YOUIFleet system. Then the mobile robots are managed to complete the material transfer and automatic loading and unloading tasks.

Key Benefits

Labor cost saving of 20 employees

Information transparency improvement and manufacturing equipment error rate reduction

Increased production efficiency by 33%

precise and efficient material loading and unloading

Intelligent Logistics Project of a World’s Leading Semiconductor 8-inch Fab

Project Overview

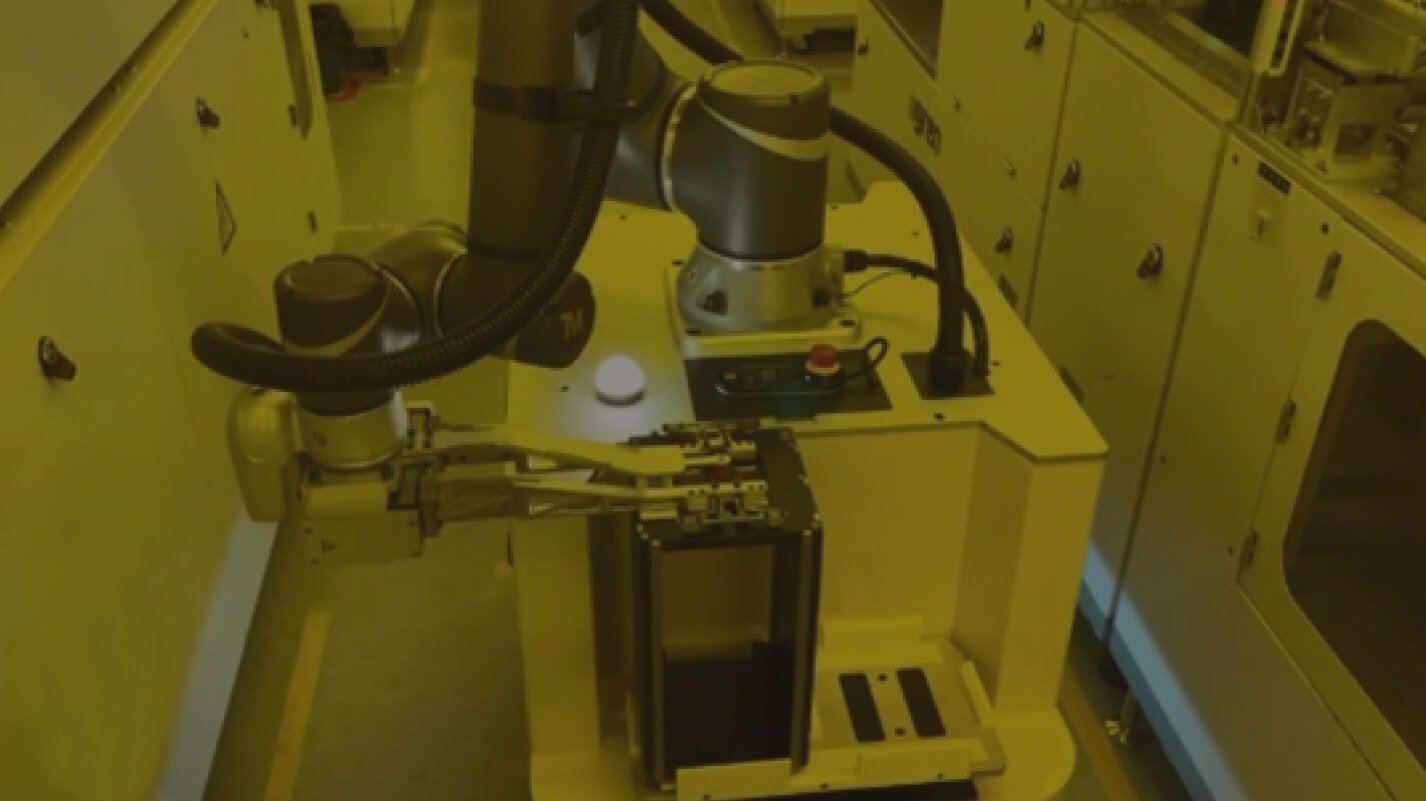

The mobile robots are deployed in the world's leading semiconductor 8-inch fab. This newly built factory is in the process of production capacity expansion. To solve the huge and complex daily tasks of SMIF Pod loading and unloading, YOUIBOT

foup handling robots are introduced to achieve fl�exible and intelligent production.

Solution

With foup handling robots and the YOUIFleet and YOUITMS systems, the factory can achieve flexible transportation and unmanned automatic loading and unloading of materials between electronic racks, manufacturing equipment, and

warehouse. The YOUITMS logistics management system directly interfaces with the equipment control system, enabling visualization of workshop production and operation control in the production process.

Key Benefits

Reduce manual work

automatic loading and unloading

Digital intelligent management with real-time feedback of production data

Reduce ineffective walking by 30%

Increase electronic rack utilization by 60%